WHIMS Tsayayyen Zobe Babban Mai Rarraba Magnetic

Aikace-aikace

Haɓakawa

Fa'idodin LHGC Akan Gargajiya Tsayayyen Zobe WIMS

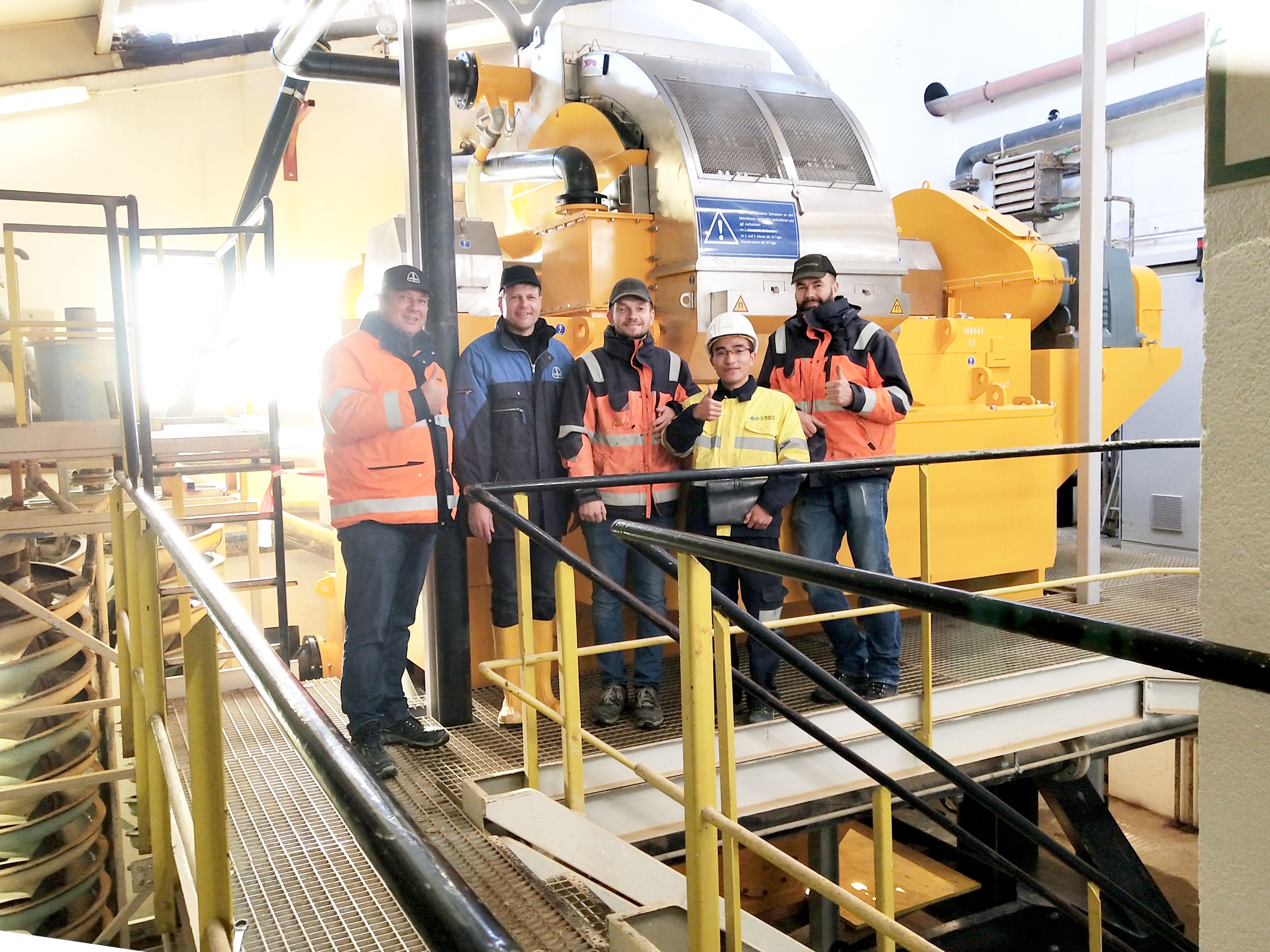

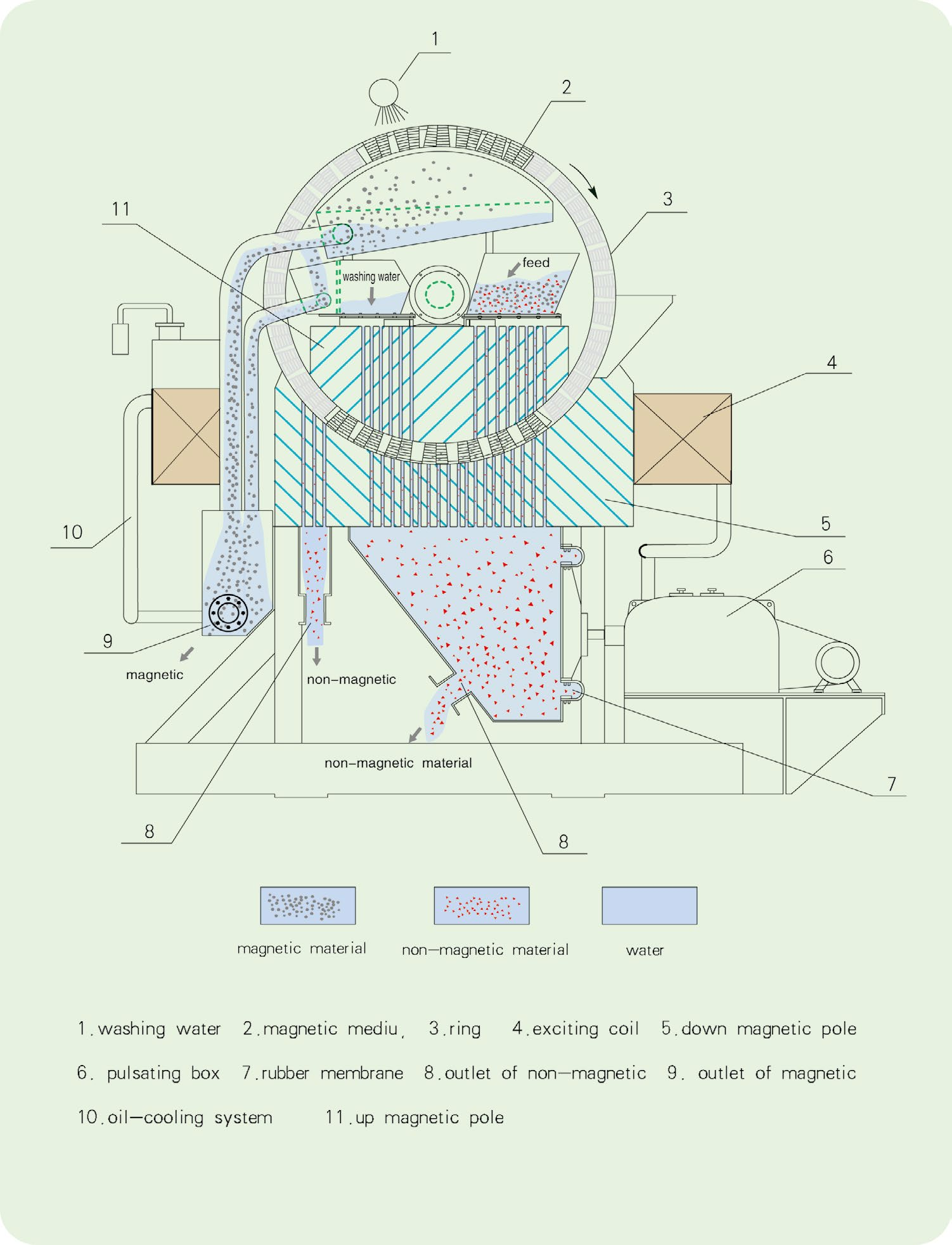

The LHGC mai-ruwa sanyaya zobe a tsaye high gradient Magnetic SEPARATOR (WHIMS) utilizes da hade da Magnetic ƙarfi, pulsating ruwa da nauyi don ci gaba da raba Magnetic da wadanda Magnetic ma'adanai. Ya mallaki abũbuwan amfãni na babban aiki iya aiki, babban fa'ida

inganci da ƙimar farfadowa, ƙananan ƙarancin zafin jiki na filin maganadisu, cikakkiyar fitarwa, da babban matakin hankali.

The LHGC a tsaye zobe high gradient Magnetic SEPARATOR (WHIMS) abin dogara da kuma sauki aiki da kuma kula, da kuma yanar-gizo na Things da Cloud Platform Technology an yi amfani da su gane fasaha atomatik aiki. Don kwatanta da na gargajiya WHIMS, LHGC ya ɗauki sabbin fasahohi da matakai da yawa, waɗanda ke inganta ingantaccen aiki yadda ya kamata, daidaiton rabuwa da ƙimar jefar wutsiya, da ƙarancin kulawa da farashin aiki.

Fasalolin Fasaha

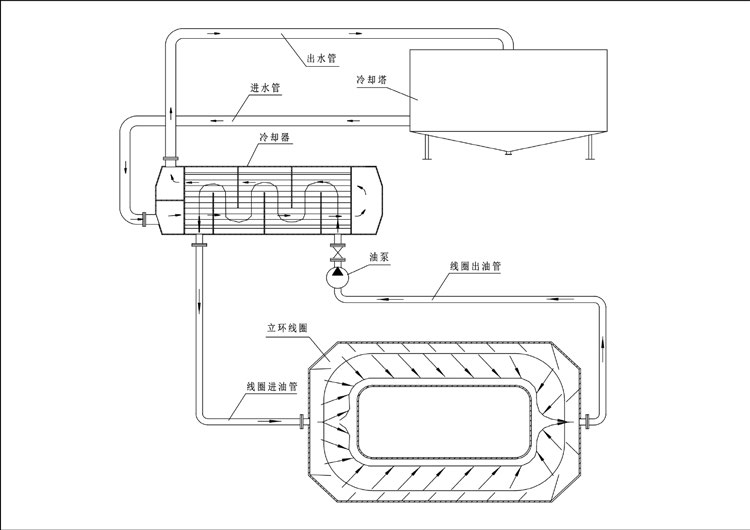

Fasahar Sayar da Zafin Mai da Ruwa

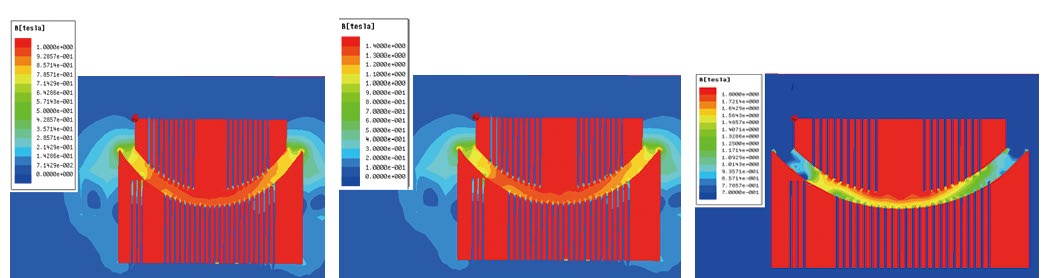

Madaidaicin Zane-zane na Magnetic

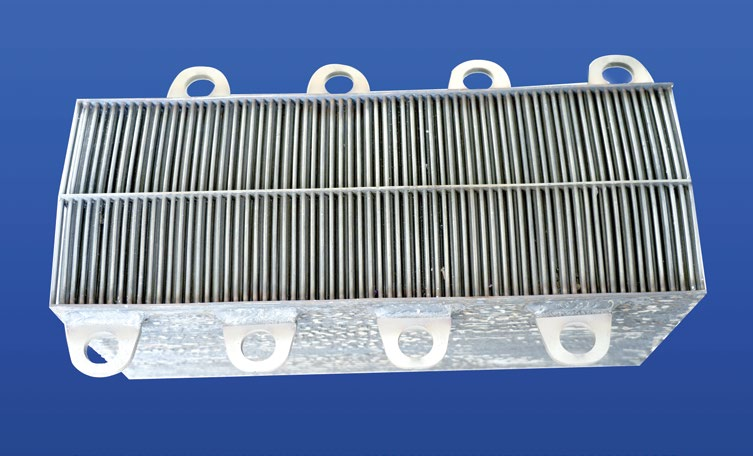

Haɗin Magnetic Matrix na tsawon rai

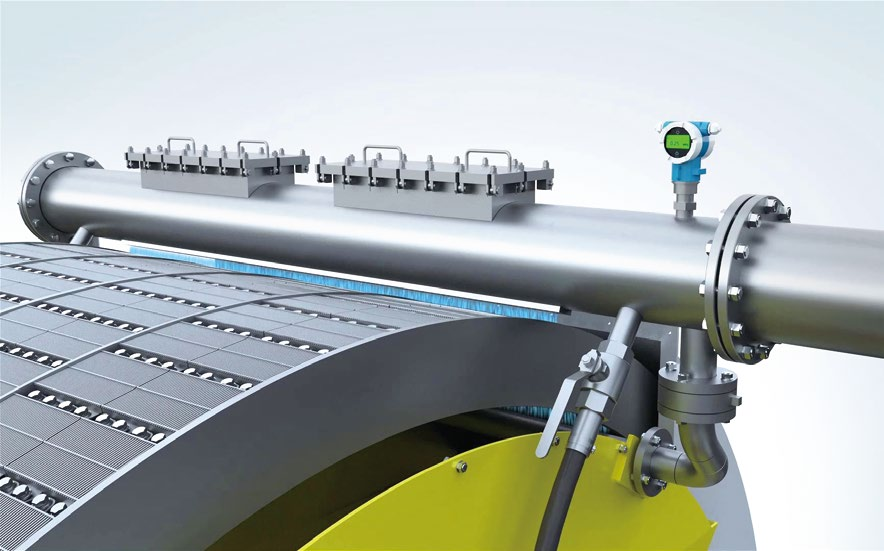

Tsarin tacewa na iska mai atomatik

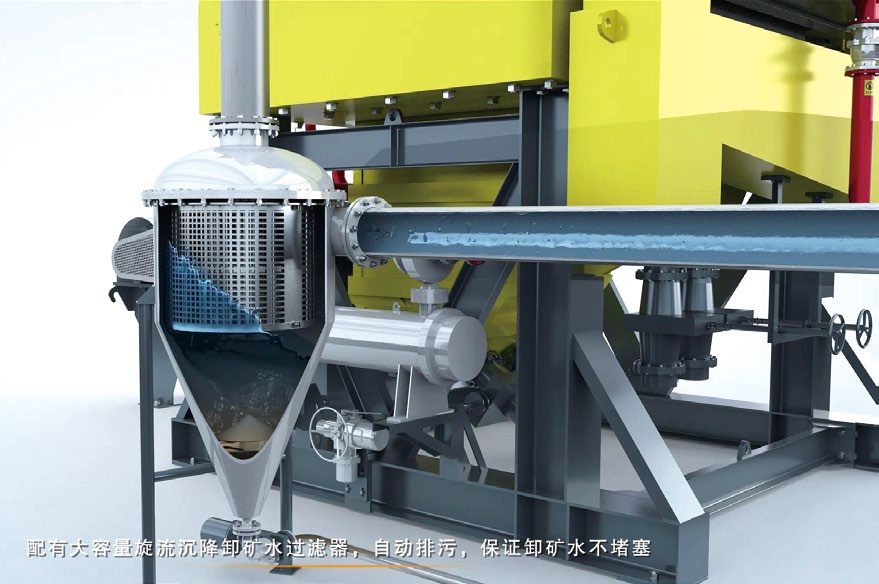

Tsarin Fitar da Ma'adinan Ruwa

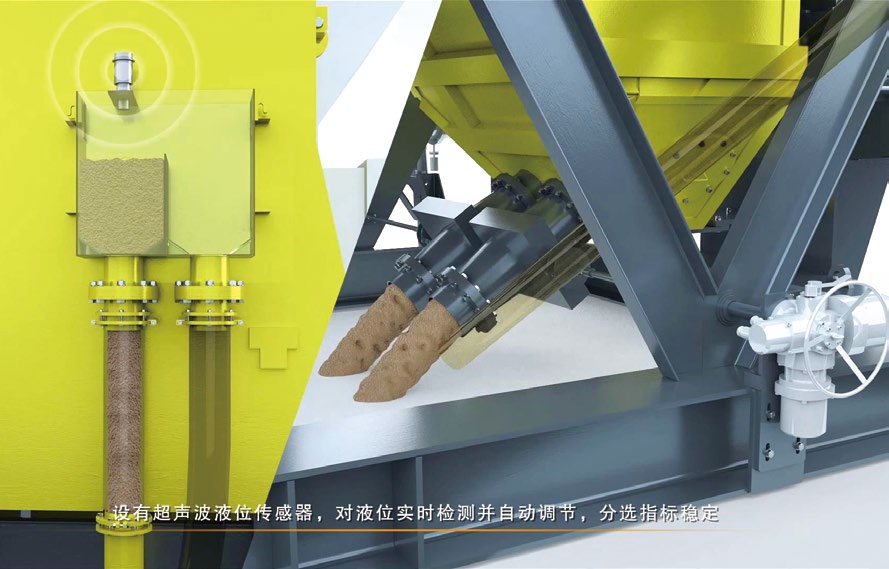

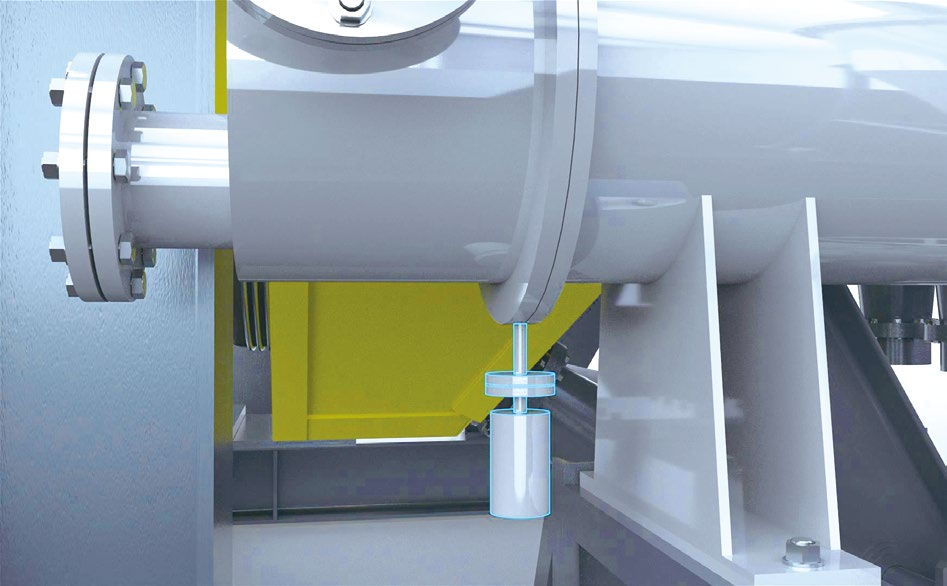

Tsarin Kulawa ta atomatik Matsayin Liquid

Ana gano yanayin canjin matakin ruwa na ɗakin rabuwa a cikin ainihin lokacin ta hanyar firikwensin ultrasonic, kuma an haɗa shi tare da mai kunna wutar lantarki, don haka matakin ruwa na ɗakin rabuwa koyaushe yana kula da mafi kyawun yanayin rabuwa; aikin hannu yana raguwa, kuma an saukar da wahalar dubawa ta hannu; Ana hana wuce kima na slurry nan take don gujewa ambaliya.

Tsarin Kariyar Ƙararrawar Zazzabi

Ana samar da na'urori masu auna zafin jiki don gano zafin aiki na nada a ainihin lokacin da mayar da bayanin zuwa cibiyar sarrafawa. Lokacin da zafin jiki na nada ya wuce ƙimar da aka saita, tsarin zai yi ƙararrawa ta atomatik, kuma kayan aikin zasu daina aiki lokacin da babban iyaka ya kai don tabbatar da amintaccen aiki na kayan aiki.

Na'urar ƙararrawa ta leka

Tsarin Lubrication Na atomatik

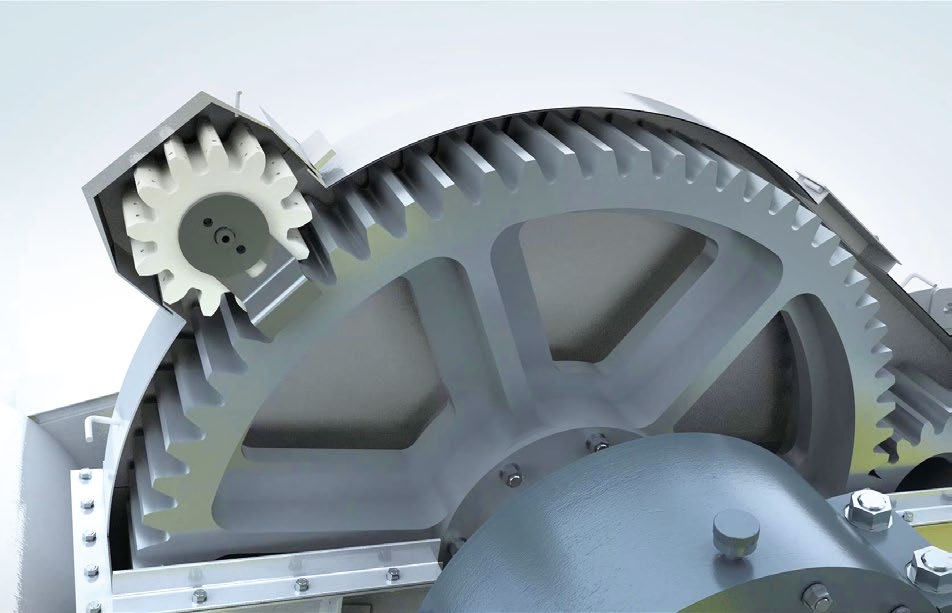

Kayan aikin zobe yana ɗaukar na'urar mai sarrafa kayan aiki ta atomatik don tabbatar da cewa kayan aikin na iya gane lubrication na atomatik ba tare da dakatar da aikin ba da haɓaka ƙimar aiki.

Platform Sabis Mai Nisa Daga Fasahar Intanet na Fasahar Abubuwa

Ƙa'idar Aiki

Ƙa'idar Aiki

Ana gabatar da slurry ɗin zuwa hopper mai ciyarwa ta bututun ciyarwa, kuma yana shiga matrix ɗin maganadisu akan zobe mai jujjuya tare da ramummuka a cikin sandar maganadisu na sama. Magnetic matrix yana maganadisu, kuma ana haifar da babban filin maganadisu a samansa. Abubuwan maganadisu

ana jan hankali a saman matrix na maganadisu, kuma ana kawo su zuwa wurin da ba na maganadisu ba a saman tare da jujjuya zoben, sa'an nan kuma a zubar da su cikin hopper ta hanyar matsa lamba ruwa. Abubuwan da ba na maganadisu ba suna gudana cikin hopper ɗin kayan da ba na maganadisu ba tare da ramummuka a cikin ƙananan sandar maganadisu don fitarwa.

Yanayin Hali