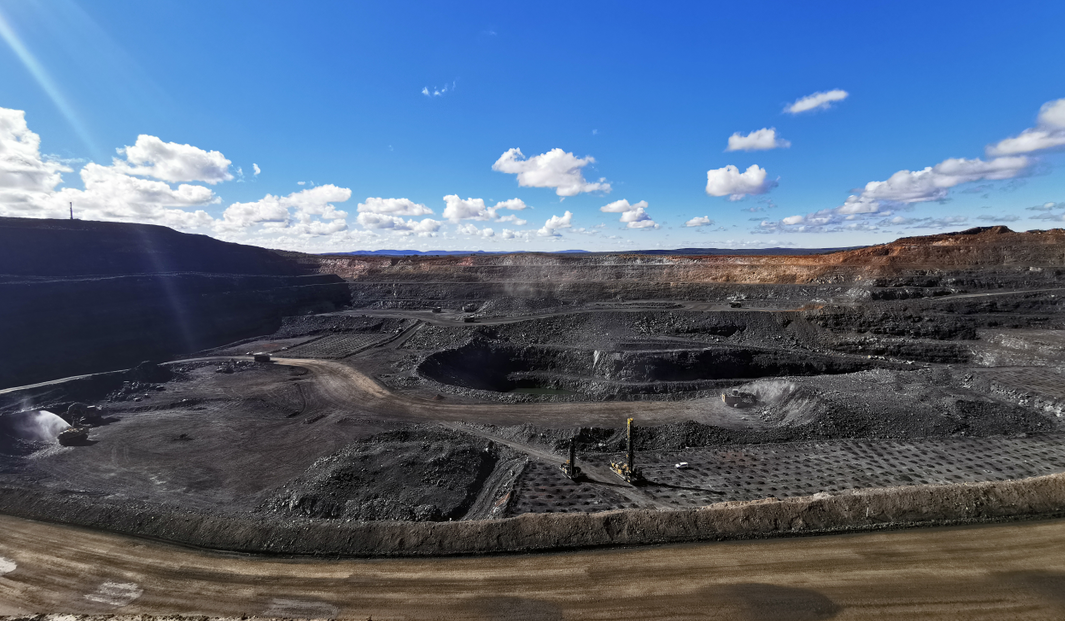

Saboda yawan hako ma'adinan karafa da ake yi a kasata, karancin albarkatunta na kara yin karanci. Don haka, abubuwan da ake bukata na kayan aikin sarrafa ma'adinai suna karuwa sosai, musamman yadda ake amfani da wutsiya gabaɗaya yana da alaƙa kai tsaye da dorewar albarkatun ƙasata. Tambayar ita ce ta yaya za a aiwatar da manufofin kiyaye makamashi, rage yawan amfani, da rage fitar da hayaki da gwamnati ta gabatar, da kiyaye amfani da albarkatu na dogon lokaci, da kuma kara darajar albarkatun ya zama wani muhimmin batu da ke fuskantar masana'antar hakar ma'adinai.

A halin yanzu, filin jirgin sama na dawo da wutsiya da ake amfani da shi wajen rarrabuwar bututun ƙarfe na ƙarfe a cikin ƙasata ya kai kusan 1600Gs, kuma yana da wahala a iya dawo da ma'adanai masu rauni a cikin wutsiya. A saboda wannan dalili, akwai buƙatar gaggawa don haɓaka na'urori masu fa'ida tare da ƙarfin fage mai ƙarfi kuma masu iya rage baƙin ƙarfe na wutsiya don haɓaka amfani da albarkatun ma'adinai a yanzu a ƙasata.

Shandong Huate Magnetoelectric Technology Co., Ltd. An sadaukar da bincike na magnetite Magnetic rabuwa wutsiyoyi dawo da kayan aiki tun 2005. A halin yanzu, babban adadin ferrite da aka samar a matsayin Magneto tailings dawo da inji, da uku jerin da aka kafa. Kayayyakin da ke da ƙayyadaddun bayanai da yawa sun zama babban kayan aiki don dawo da wutsiya. Don ƙara haɓaka ƙarfin dawo da ƙarfe na kayan aikin dawo da wutsiya, bayan cikakken bincike, gwaji da gwaje-gwajen bincike, yin amfani da kayan magnetic baƙin ƙarfe neodymium boron da kuma hanyar saukewa a cikin yankin da ba na Magnetic ba ya kara inganta ƙarfin dawo da ƙarfe. , kuma saukewa yana da sauƙi, wanda zai iya biyan bukatun amfani.

Tsari da ƙa'idar aiki na tsakiyar filin ƙarfi Semi-magnetic kai sauke wutsiyoyi dawo da inji

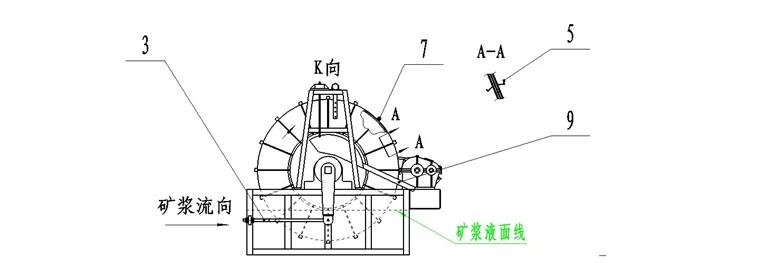

Na'ura mai ƙarfi ta tsakiya mai ƙarfi ta Semi-magnetic juji tailing dawo da injin yana amfani da boron baƙin ƙarfe neodymium azaman kayan maganadisu. Wurin rabuwa yana da matsakaicin yanki na maganadisu da yanki mai rauni mai rauni. Sandunan maganadisu a madadin su suna samar da tsarin maganadisu na zobe mai madauwari. Ana ba da calo mai jujjuyawa a wajen tsarin maganadisu. , An daidaita tsarin maganadisu, wani ɓangare na harsashi yana nutsewa a cikin ɓangaren litattafan almara, kuma ƙwayoyin magnetic a cikin ɓangaren litattafan almara suna ci gaba da shayarwa ta hanyar ci gaba da juyawa. Kwayoyin maganadisu na ci gaba da rugujewa tare da jujjuyawar casing, ta yadda abubuwan da ba na maganadisu ba a cikin kayan maganadisu suna ci gaba da wanke su. Babban ɓangaren dama na tsarin maganadisu na rabin-annular ba shi da filin maganadisu. Lokacin da kayan maganadisu suka shiga yankin da ba na maganadisu ba, a ƙarƙashin aikin ruwan wanka da nauyi na kayan, sauke kayan cikin tanki mai tattarawa.

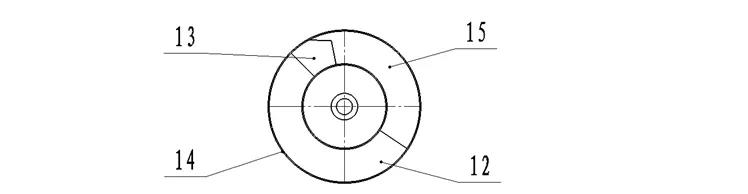

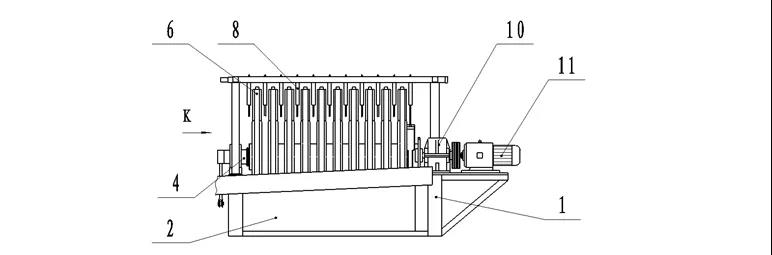

Ƙarfin tsakiyar filin Semi-magnetic kai-ɗorawa wutsiya na'ura mai dawo da kayan aiki shine tsarin haɗin nau'in diski, kuma ana iya ƙididdige adadin fayafai na maganadisu bisa ga buƙatun ikon sarrafawa. An nuna tsarinsa a cikin Hoto 1, 2, da 3. 1- firam; 2- tanki mai slurry; 3- tsarin daidaita faifai; 4- shinge na tsakiya; 5- mai karkatarwa; 6- tire mai tarawa; 7- toshe mai tada hankali; 8- bututu mai zubar da ruwa; 9- riko da tsinke; 10 -Mai Ragewa; 11-motoci; 12-karfin maganadisu; 13-rauni Magnetic yanki; 14-kafaffen faifai; 15-ba Magnetic yanki.

Firam ɗin an yi shi da ƙarfe mai walda kuma ana amfani da shi galibi don tallafawa shingen tsakiya, shigar da tsarin watsawa da shigar da tankin slurry.

Faifan maganadisu wani tsari ne na sintirin maganadisu, kuma an shigar da faifan tattarawa a waje, ana yin sandwiched farantin maganadisu a tsakanin karfen maganadisu biyu, sannan kasan faifan tattarawa yana nutsewa cikin tankin slurry 2.

Ana ba da faifan maganadisu tare da filin maganadisu na tsakiya, filin maganadisu mai rauni da wurin da ba na maganadisu ba, kuma an kafa shi akan tsakiyar axis.

Ana ba da ƙofofin biyu na kwanon tarawa tare da nau'in faranti na jagora waɗanda aka rarraba a cikin siffa mai haske, kuma ana ba da nau'in tubalan da aka rarraba daidai-da-wane a gefen waje.

A halin yanzu, wasu masu tattarawa a cikin ƙasata suna amfani da injunan dawo da wutsiya mai matsakaici-filin ƙarfi, amma saboda ƙarancin ƙarancin lalacewa, kayan maganadisu zasu tsotse baya lokacin da kayan maganadisu ya shiga wurin da ba na maganadisu ba daga matsakaicin filin maganadisu, kuma faifai da scraper suna sawa da sauri. , Dangane da wasu ƙuntatawa da ake amfani da su.

Dangane da halin da ake ciki a sama, kamfaninmu yana ɗaukar faifan tsakiya na tsakiya-ƙarfi na rabin-annular tare da cikakken tsari na neodymium-iron-boron wanda za a gyara shi a kan tsakiya na tsakiya, kuma an daidaita tsakiyar tsakiya ba tare da juyawa ba. Mai jujjuya kwanon tattarawa, ƙananan ɓangaren kwanon ɗin tattara yana nitsewa a cikin ɗigon ruwa don ɗaukar kayan maganadisu. Ana amfani da mota da na'ura mai ragewa don fitar da tray ɗin tattarawa don jujjuya, kuma abin da aka lallaɓawa yana wucewa ta tsakiyar filin maganadisu da raunin ƙarfin maganadisu, sannan kuma ya fita bayan an isa filin da ba na maganadisu ba, wanda ke magance matsalolin da ke sama.

Ana shirya tsintsiya madaurinki ɗaya tsakanin kowane kwanon da ake tarawa, kuma kayan maganadisu akan kwanon tattarawa ana wanke su kuma suna gudana tare da tsinken kayan.

Tsarin watsawa yana kunshe da motar jujjuyawar mita, mai ragewa, haɗin gwiwa, hannun rigar watsawa, da dai sauransu. An shigar da sassan da aka ambata a sama a kan shinge na tsakiya da kuma firam don gane ci gaba da jujjuyawar tiren tattarawa.

The kula hukuma sanye take da inverters, iko switches da sauran sassa don sarrafa juyi gudun Magnetic faifai a kowane lokaci.

Wurin maganadisu na dindindin a cikin wurin maganadisu ya ƙunshi yanki ɗaya ko guda da yawa a cikin jagorar kauri, kuma kafaffen gidan yanar gizon diski yana sandwiched a tsakiya. Yankin maganadisu yana ɗaukar nau'i-nau'i-nau'i-nau'i-nau'i-nau'i-nau'i-nau'i na maganadisu tare da kishiyar polarities waɗanda za a shirya su dabam. A yayin ci gaba da jujjuyawar kwanon tattarawa, kayan maganadisu koyaushe suna faɗuwa a cikin kwanon tattarawa da kuma cikin ruwa don wankewa da ɓata ruwa, ta yadda kayan maganadisu da aka kwato ana haɗa su da wutsiya na yau da kullun. Idan aka kwatanta da na'urar sake yin amfani da ita, tsarki ya fi girma kuma tasirin sake yin amfani da shi ya fi kyau.

An saita yankin maganadisu mai rauni tsakanin filin maganadisu da yankin mara maganadisu a cikin faifai. Lokacin da kayan maganadisu ya shiga cikin yankin da ba na maganadisu ba, saboda raunin filin jujjuyawar filin maganadisu da yanki mai rauni na filin maganadisu a hankali yana raguwa, yanayin ƙaura na baya na kayan maganadisu yana raguwa sosai. Maƙasudin karkata akan tiren kayan shima yana hana motsin baya na kayan maganadisu da zubewar kayan, kuma yana iya sa kayan maganadisu su yi ƙasa a hankali. Saboda aikin nauyi da ruwan wanka, ana samun saurin saukewa.

Tire ɗin tattarawa ƙaƙƙarfan tsari ne kuma cikakken hatimi, kuma saman don tallata kayan maganadisu ya ƙunshi kayan da ba na maganadisu ba. A kan tiren tattarawa, farantin jagora yana da haƙarƙari a waje, wanda ke karkata a wani kusurwa tare da ƙarshen ƙarshen tiren tattarawa. Babban manufar ita ce hana magnetism. Komawar kayan baya da yayyo kayan. Domin a rage yawan ajiyar tama, ana shirya nau'in ɓangarorin motsa jiki don zuga tama a kusa da kwanon ɗin tattarawa, kuma a lokaci guda, zubar da farantin tattarawa saboda ajiya na takin yana raguwa. .

Aikace-aikacen samar da masana'antu

Nazari na dawo da tasirin tsaka-tsakin ƙarfin Semi-magnetic kai sauke wutsiyoyi dawo da inji

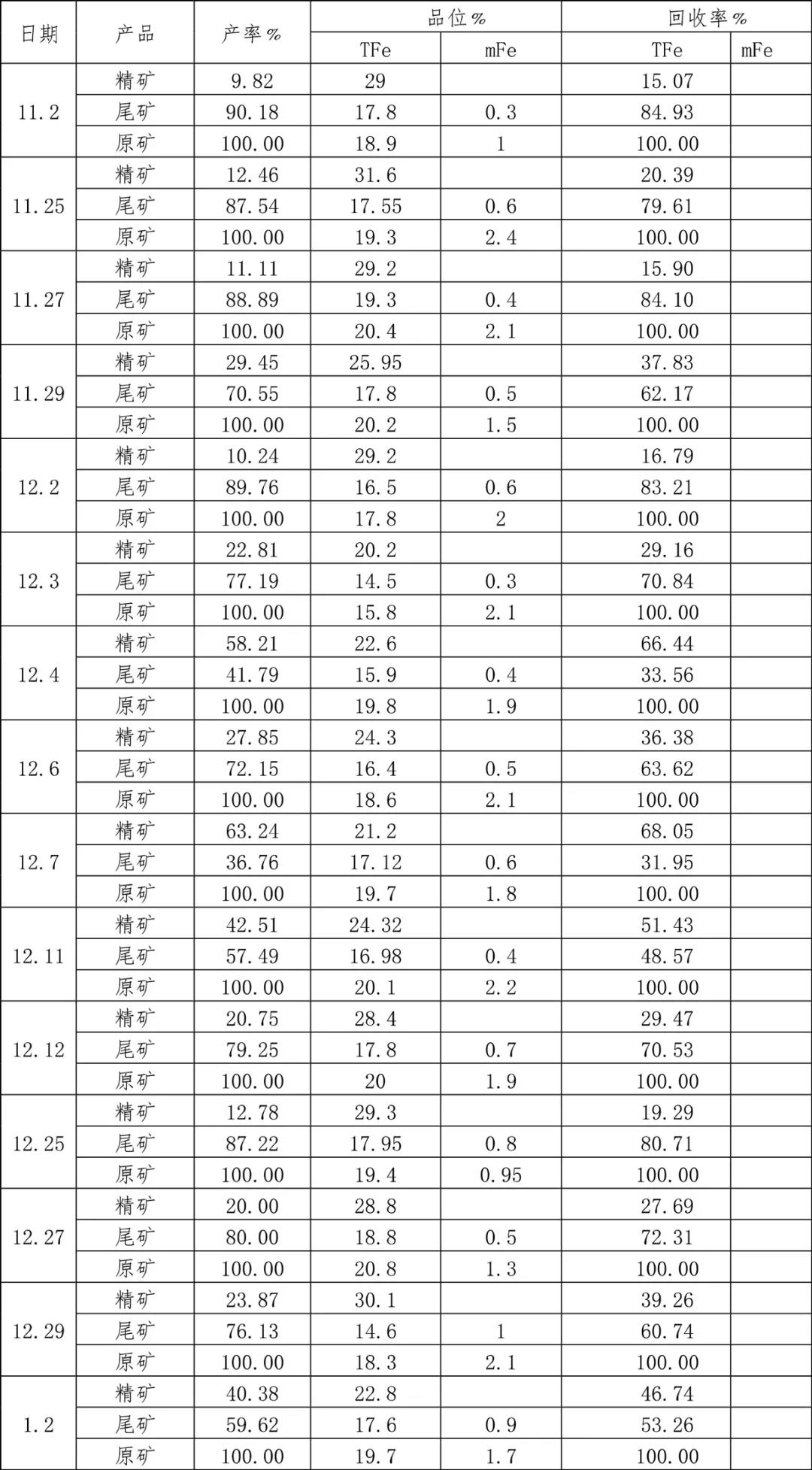

A matsakaici-filin ƙarfi Semi-magnetic kai sauke wutsiyoyi dawo da inji tare da samfurin YCBW-15-8 sa a yi amfani da wani kamfanin hakar ma'adinai aka shigar a bayan wutsiya dawo da inji hada da ferrite a cikin Magnetic tsarin. Bayan fiye da rabin shekara na aiki, Kayan aiki yana aiki akai-akai kuma tasirin dawowa yana da kyau. Bayan gwaje-gwajen samfur da yawa, sakamakon yana da gamsarwa. Sakamakon gwaje-gwajen samfuri da yawa sune kamar haka:

Ta hanyar binciken bayanan da ke sama:

Sakamakon farfadowa na wannan kayan aiki: an rage darajar wutsiya da kashi 2.16 bayan an rarraba, an rage ma'aunin ƙarfe na Magnetic da 1.27% bayan rarrabawa, kuma matsakaicin matsakaicin ma'adinai na tsakiya shine 26.53%. Tasirin farfadowa a bayyane yake.

Hasashen kasuwa da fa'idojin tattalin arziki

A halin yanzu, akwai kamfanoni da yawa na Magnetic Separation a kasar Sin, kuma kaɗan ne kawai daga cikinsu ke amfani da injunan dawo da wutsiya, amma ba sa amfani da injunan dawo da wutsiya masu matsakaicin ƙarfi. Saboda haka, tsammanin kasuwa yana da fadi. Idan 20% na Magnetic Plant Plant zuba jari a cikin wannan kayan aiki, ƙididdiga bisa 300 raka'a a kowace shekara da model YCBW-15-8. Kowace naúrar na iya dawo da busasshen taman 7t/h a kowace awa, 168t/h na busasshiyar taman kowace rana, da kuma kwanaki 330 na aiki a kowace shekara, jimlar tan miliyan 55.44, kuma jimlar tan miliyan 16.632 an sake yin amfani da su ta hanyar raka'a 300. Amfanin tattalin arziki yana da yawa, kuma amfani da wannan kayan aiki na iya rage barnatar da albarkatun ma'adinai masu yawa ga ƙasar kowace shekara.

A halin yanzu, darajar wutsiya ta ferrous a ƙasata tana da yawa bayan rarrabuwa, yana haifar da ɓarna mai yawa. Albarkatun ma'adinai sune tushen rayuwa da ci gaban ɗan adam. Fiye da kashi 95% na makamashi da kashi 80% na albarkatun masana'antu a ƙasata ana samun su ne daga ma'adinai. Tare da saurin bunkasuwar tattalin arzikin kasata, bukatar albarkatun ma'adinai na ci gaba da karuwa. A daya bangaren, albarkatun ma'adinai na kasata na fuskantar matsin lamba daga karanci. Ma'adinan ma'adinai masu girma, masu sauƙin rarrabawa suna raguwa, kuma ƙananan ma'adanai, masu wuyar warwarewa suna ƙara daraja. Haɓaka da bincike na injunan dawo da wutsiya sama da 300mT yana da tasiri mai kyau akan rage sharar albarkatun ƙasa da haɓaka ƙimar amfani da albarkatun ma'adinai. Daga hangen nesa na ci gaba da tasirin aikace-aikacen, ya inganta ingantaccen adadin dawo da ma'adinai. Ya dace da buƙatun ƙira kuma samfur ne wanda ya cancanci haɓakawa da aikace-aikace.

Lokacin aikawa: Mayu-12-2021