Tare da kaddarorin jiki na musamman da sinadarai, kaolin shine ma'adinan ma'adinan da ba makawa ba a cikin tukwane, yin takarda, roba, robobi, refractories, tace man fetur da sauran fannonin fasaha na masana'antu da aikin gona da tsaron ƙasa. Farin kaolin alama ce mai mahimmanci na ƙimar aikace-aikacen sa.

Abubuwan da ke shafar farin kaolin

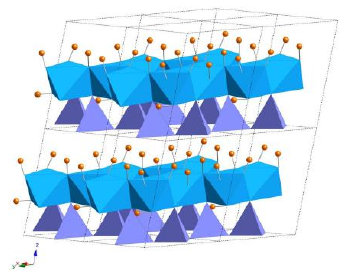

Kaolin wani nau'i ne na yumbu mai laushi ko dutsen yumbu wanda ya ƙunshi ma'adanai na kaolinite. Tsarin sinadarai na crystal shine 2SiO2 · Al2O3 · 2H2O. Ƙananan ma'adanai marasa yumbu sune ma'adini, feldspar, ma'adinan ƙarfe, titanium, aluminum hydroxide da oxides, kwayoyin halitta, da dai sauransu.

Tsarin crystalline na kaolin

Dangane da yanayi da yanayin ƙazanta a cikin kaolin, ƙazantar da ke haifar da raguwar farin kaolin za a iya kasu kashi uku: Organic carbon; Abubuwan launi, kamar Fe, Ti, V, Cr, Cu, Mn, da sauransu; Ma'adanai masu duhu, irin su biotite, chlorite, da dai sauransu. Gabaɗaya, abubuwan da ke cikin V, Cr, Cu, Mn da sauran abubuwan da ke cikin kaolin kadan ne, wanda ba shi da tasiri a kan fari. Abubuwan da ke cikin ma'adinai da abun ciki na ƙarfe da titanium sune manyan abubuwan da ke shafar farin kaolin. Kasancewarsu ba wai kawai zai shafi farar kaolin ne kawai ba, har ma zai shafi launin fata. Musamman kasancewar baƙin ƙarfe oxide yana da mummunan tasiri akan launi na yumbu kuma yana rage haske da juriya na wuta. Kuma ko da adadin oxide, hydroxide da hydrated oxide na baƙin ƙarfe oxide ne 0.4%, ya isa ya ba da laka na yumbu ja zuwa rawaya canza launi. Wadannan baƙin ƙarfe oxides da hydroxides na iya zama hematite (ja), maghemite (ja-kasa-kasa), goethite (brownish yellow), limonite (orange), hydrated iron oxide (brownish ja), da dai sauransu. a cikin kaolin yana taka muhimmiyar rawa wajen ingantaccen amfani da kaolin.

Halin da ke faruwa na sinadarin ƙarfe

Halin da ke faruwa na baƙin ƙarfe a cikin kaolin shine babban abin da ke ƙayyade hanyar cire ƙarfe. Yawancin karatu sun yi imanin cewa baƙin ƙarfe na crystalline a cikin nau'i mai kyau yana haɗuwa a cikin kaolin, yayin da baƙin ƙarfe amorphous ya kasance mai rufi a saman ƙananan ƙwayoyin kaolin. A halin yanzu, yanayin da ke faruwa na baƙin ƙarfe a cikin kaolin ya kasu kashi biyu a gida da waje: ɗaya yana cikin kaolinite da kuma ma'adanai (irin su mica, titanium dioxide da illite), wanda ake kira structural iron; Ɗayan yana cikin nau'i na ma'adinan ƙarfe mai zaman kansa, wanda ake kira baƙin ƙarfe kyauta (ciki har da ƙarfe na sama, ƙarfe mai kyau na crystalline da baƙin ƙarfe amorphous).

Iron da aka cire ta hanyar cire baƙin ƙarfe da farar fata na kaolin ƙarfe ne na kyauta, wanda ya haɗa da magnetite, hematite, limonite, siderite, pyrite, ilmenite, jarosite da sauran ma'adanai; Yawancin baƙin ƙarfe yana samuwa a cikin nau'i na colloidal limonite da aka tarwatsa sosai, da ƙaramin adadin a cikin nau'i mai siffar zobe, acicular da goethite mara kyau da kuma hematite.

Hanyar kawar da ƙarfe da farar fata na kaolin

Rabuwar ruwa

Ana amfani da wannan hanya galibi don cire ma'adanai masu lalacewa irin su quartz, feldspar da mica, da ƙazanta masu ƙarfi kamar tarkacen dutse, da kuma wasu ma'adanai na ƙarfe da titanium. Ba za a iya cire ma'adinan ƙazanta masu kama da yawa da solubility ga kaolin ba, kuma haɓakar fari ba a bayyane yake ba, wanda ya dace da fa'ida da farar fata na kaolin tama mai inganci.

Magnetic rabuwa

Rarraba ma'adinan ƙarfe a cikin kaolin yawanci maganadisu rauni ne. A halin yanzu, babban gradient karfi Magnetic rabuwa Hanyar ne yafi amfani, ko kuma rauni Magnetic ma'adanai an canza zuwa wani karfi Magnetic baƙin ƙarfe oxide bayan gasa, sa'an nan cire ta talakawa Magnetic rabuwa hanya.

A tsaye zobe high gradient maganadisu SEPARATOR

High gradient Magnetic separator ga electromagnetic slurry

Low zazzabi superconducting maganadisu SEPARATOR

Hanyar yin iyo

An yi amfani da hanyar flotation don kula da kaolin daga ajiya na farko da na sakandare. A cikin tsarin flotation, kaolinite da mica barbashi sun rabu, kuma samfuran da aka tsarkake sun dace da albarkatun masana'antu da yawa. Zaɓin zaɓin flotation na kaolinite da feldspar yawanci ana yin su a cikin slurry tare da pH mai sarrafawa.

Hanyar ragewa

Hanyar ragewa ita ce yin amfani da wakili mai ragewa don rage ƙazantattun baƙin ƙarfe (kamar hematite da limonite) a cikin yanayin kaolin trivalent zuwa ions baƙin ƙarfe mai narkewa, wanda ake cirewa ta hanyar tacewa da wankewa. Ana samun kawar da ƙazantattun Fe3+ daga kaolin masana'antu yawanci ta hanyar haɗa fasaha ta jiki (rarrabuwar maganadisu, flocculation zaɓi) da jiyya na sinadarai a ƙarƙashin acidic ko rage yanayi.

Sodium hydrosulfite (Na2S2O4), wanda kuma aka sani da sodium hydrosulfite, yana da tasiri wajen ragewa da fitar da baƙin ƙarfe daga kaolin, kuma a halin yanzu ana amfani dashi a masana'antar kaolin. Koyaya, dole ne a aiwatar da wannan hanyar a ƙarƙashin yanayi mai ƙarfi na acidic (pH <3), wanda ke haifar da hauhawar farashin aiki da tasirin muhalli. Bugu da ƙari, abubuwan sinadarai na sodium hydrosulfite ba su da ƙarfi, suna buƙatar ajiya na musamman da tsada da shirye-shiryen sufuri.

Thiourea dioxide: (NH2) 2CSO2, TD) wakili ne mai ƙarfi mai ragewa, wanda ke da fa'idodin rage ƙarfi mai ƙarfi, abokantaka na muhalli, ƙarancin lalata, aminci da ƙarancin farashi na samar da tsari. Fe3+ da ba a iya narkewa a cikin kaolin ana iya rage shi zuwa mai narkewa Fe2+ ta TD.

Bayan haka, ana iya ƙara farin kaolin bayan tacewa da wankewa. TD yana da ƙarfi sosai a yanayin zafi da kuma tsaka tsaki. Ƙarfin rage ƙarfin TD zai iya samuwa ne kawai a ƙarƙashin yanayin ƙarfin alkalinity (pH> 10) ko dumama (T> 70 ° C), wanda ya haifar da farashin aiki da wahala.

Hanyar oxidation

Maganin oxidation ya haɗa da amfani da ozone, hydrogen peroxide, potassium permanganate da sodium hypochlorite don cire murfin carbon da aka tallata don inganta fata. Kaolin a cikin wuri mai zurfi a ƙarƙashin nauyin nauyi yana da launin toka, kuma ƙarfe a cikin kaolin yana cikin yanayin raguwa. Yi amfani da magunguna masu ƙarfi kamar ozone ko sodium hypochlorite don oxidize FeS2 maras narkewa a cikin pyrite zuwa mai narkewa Fe2+, sannan a wanke don cire Fe2+ daga tsarin.

Hanyar leaching acid

Hanyar leaching acid shine canza ƙazantattun baƙin ƙarfe a cikin kaolin zuwa abubuwa masu narkewa a cikin maganin acidic (hydrochloric acid, sulfuric acid, oxalic acid, da sauransu), don haka fahimtar rabuwa da kaolin. Idan aka kwatanta da sauran kwayoyin acid, ana ɗaukar acid oxalic a matsayin mafi alƙawari saboda ƙarfin acid ɗinsa, kyawawan kayan haɓakawa da haɓakar haɓakawa. Tare da oxalic acid, baƙin ƙarfe narkar da za a iya haɗe shi daga maganin leaching a cikin nau'i na oxalate na ferrous, kuma ana iya ƙara sarrafa shi don samar da hematite mai tsabta ta hanyar calcination. Ana iya samun acid oxalic a cikin arha daga sauran hanyoyin masana'antu, kuma a cikin matakin harbe-harbe na masana'antar yumbu, duk wani ragowar oxalate a cikin kayan da aka kula da shi zai lalace zuwa carbon dioxide. Yawancin masu bincike sun yi nazarin sakamakon narkar da baƙin ƙarfe oxide tare da oxalic acid.

Hanyar ƙididdige yawan zafin jiki

Calcination shine tsarin samar da samfuran kaolin na musamman. Dangane da yanayin zafin jiyya, ana samar da nau'o'in kaolin daban-daban guda biyu. Calcination a cikin kewayon zafin jiki na 650-700 ℃ yana kawar da rukunin hydroxyl tsarin, kuma tururin ruwa mai gujewa yana haɓaka elasticity da opacity na kaolin, wanda shine ingantaccen sifa na aikace-aikacen shafi na takarda. Bugu da kari, ta dumama kaolin a 1000-1050 ℃, shi ba zai iya ba kawai ƙara abradability, amma kuma samun 92-95% fari.

Chlorination calcination

An cire baƙin ƙarfe da titanium daga ma'adinan yumbu, musamman kaolin ta hanyar chlorination, kuma an sami sakamako mai kyau. A cikin aiwatar da chlorination da calcination, a babban zafin jiki (700 ℃ - 1000 ℃), kaolinite ya sha dehydroxylation don samar da metakaolinite, kuma a mafi yawan zafin jiki, spinel da mullite matakai an kafa. Waɗannan sauye-sauye suna ƙara haɓakar hydrophobicity, taurin kai da girman barbashi ta hanyar sintiri. Ana iya amfani da ma'adinan da aka yi amfani da su ta wannan hanya a masana'antu da yawa, kamar takarda, PVC, roba, robobi, adhesives, goge baki da man goge baki. Babban hydrophobicity yana sa waɗannan ma'adanai su dace da tsarin kwayoyin halitta.

Hanyar microbiological

Fasahar tsabtace ƙananan ƙwayoyin cuta na ma'adanai sabon abu ne na sarrafa ma'adinai, gami da fasahar leaching microbial da fasahar flotation microbial. The microbial leaching fasaha na ma'adinai fasahar hakar ne da yin amfani da zurfin hulda tsakanin microorganisms da ma'adanai don halaka crystal lattice na ma'adanai da kuma narkar da amfani sassa. Za a iya tsarkake pyrite da sauran sulfide ores da ke cikin kaolin ta hanyar fasahar cire ƙananan ƙwayoyin cuta. Kwayoyin da aka fi amfani da su sun haɗa da Thiobacillus ferrooxidans da Fe-reducing bacteria. Hanyar microbiological yana da ƙarancin farashi da ƙarancin gurɓataccen muhalli, wanda ba zai shafi abubuwan zahiri da sinadarai na kaolin ba. Sabuwar hanyar tsarkakewa ce da farar fata tare da haɓaka haɓakar ma'adinan kaolin.

Takaitawa

Maganin cire baƙin ƙarfe da farar fata na kaolin yana buƙatar zaɓar hanya mafi kyau bisa ga dalilai masu launi daban-daban da manufofin aikace-aikacen daban-daban, inganta ingantaccen aikin ma'adinai na kaolin, da sanya shi yana da ƙimar amfani da ƙimar tattalin arziki. Halin ci gaba na gaba ya kamata ya zama haɗakar halayen hanyar sinadarai, hanyar jiki da hanyar microbiological ta jiki, don ba da cikakkiyar wasa ga fa'idodin su da kuma hana rashin amfani da gazawar su, don cimma sakamako mafi kyau. Har ila yau, ya zama dole a kara nazarin sabon tsarin hanyoyin kawar da kazanta daban-daban da kuma inganta tsarin da za a yi don kawar da baƙin ƙarfe da farar fata na kaolin ta hanyar kore, inganci da ƙananan carbon.

Lokacin aikawa: Maris-02-2023