Kaolin yana da rijiyoyi masu yawa a cikin ƙasata, kuma wuraren da aka tabbatar da su sun kai tan biliyan 3, galibi ana rarraba su a Guangdong, Guangxi, Jiangxi, Fujian, Jiangsu da sauran wurare. Saboda dalilai daban-daban na samuwar ƙasa, abun da ke ciki da tsarin kaolin daga sassa daban-daban na samarwa ma sun bambanta. Kaolin nau'in siliki ne mai nau'in 1: 1, wanda ya ƙunshi octahedron da tetrahedron. Babban abubuwan da ke cikin sa sune SiO2 da Al203. Hakanan ya ƙunshi ƙaramin adadin Fe203, Ti02, MgO, CaO, K2O da Na2O, da dai sauransu. Kaolin yana da kyawawan kaddarorin jiki da sinadarai da halaye na tsari, don haka ana amfani da shi sosai a cikin petrochemicals, yin takarda, kayan aiki, sutura, yumbu, kayan da ba su da ruwa, da sauransu. Tare da ci gaban kimiyya da fasaha na zamani, sabbin amfani da kaolin. suna ci gaba da fadadawa, kuma sun fara kutsawa cikin filaye masu tsayi, daidai kuma masu yankewa. Kaolin tama ya ƙunshi ƙaramin adadin (yawanci 0.5% zuwa 3%) na ma'adanai na ƙarfe (iron oxides, ilmenite, siderite, pyrite, mica, tourmaline, da sauransu), waɗanda ke canza launin kaolin kuma suna shafar launin fata da sauran kaddarorin suna iyakance aikace-aikacen. na kaoli. Don haka, nazarin abubuwan da ke tattare da kaolin da bincike kan fasahar kawar da ƙazanta suna da mahimmanci musamman. Waɗannan ƙazanta masu launin yawanci suna da raunin maganadisu kuma ana iya cire su ta hanyar rabuwar maganadisu. Rabewar Magnetic hanya ce ta raba barbashi na ma'adinai a cikin filin maganadisu ta hanyar amfani da bambancin maganadisu na ma'adanai. Don ma'adinan maganadisu masu rauni, ana buƙatar babban filin maganadisu mai ƙarfi don rabuwar maganadisu.

Tsari da ƙa'idar aiki na HTDZ high gradient slurry Magnetic SEPARATOR

1.1 Tsarin slurry electromagnetic high gradient Magnetic SEPARATOR

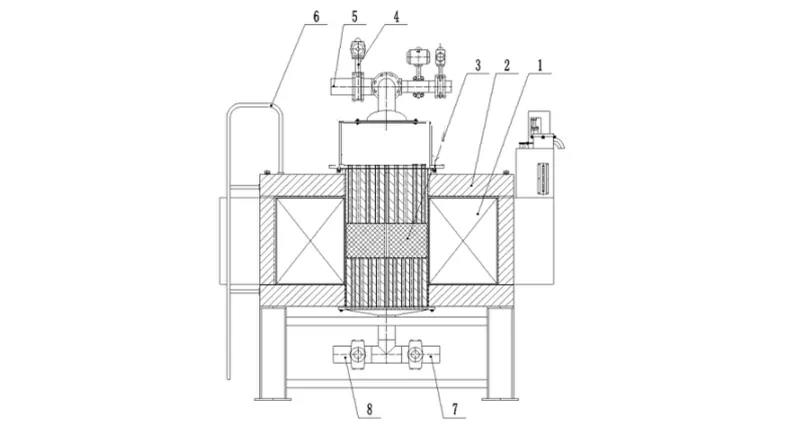

Injin yana kunshe da firam, mai sanyaya kuzari mai sanyaya mai, tsarin maganadisu, matsakaicin rabuwa, tsarin sanyaya coil, tsarin flushing, mashigar tama da tsarin fitarwa, tsarin sarrafawa, da sauransu.

Hoto 1 Tsarin tsari na babban gradient maganadisu don slurry electromagnetic

1- Na'ura mai ban sha'awa 2- Tsarin Magnetic 3- Rarraba matsakaici 4- Bawul mai ɗaukar nauyi 5- Bututun fitar da ruwa.

6-Escalator 7-bututu mai shiga 8-Slag fidda bututu

1.2 Fasaha halaye na HTDZ electromagnetic slurry high gradient Magnetic SEPARATOR

◎Fasahar sanyaya mai: Ana amfani da mai mai kwantar da hankali sosai don sanyaya, ana yin musayar zafi ta amfani da ka'idar musayar zafi mai-ruwa, kuma an karɓi babban famfo mai canza diski mai gudana. Man mai sanyaya yana da saurin zagayawa, ƙarfin musanya zafi mai ƙarfi, ƙarancin zafin wuta, da ƙarfin filin maganadisu.

◎Gyaran halin yanzu da fasahar daidaitawa na yanzu: Ta hanyar rectifier module, barga halin yanzu fitarwa aka gane, da kuma tashin hankali halin yanzu ana gyara bisa ga halaye na daban-daban kayan don tabbatar da barga Magnetic filin ƙarfi da cimma mafi kyau beneficiation index.

◎Babban kogon sulke mai sulke mai babban aiki na fasaha na maganadisu na zahiri: Yi amfani da sulke na baƙin ƙarfe don naɗe coil ɗin mara ƙarfi, ƙirƙira madaidaicin tsarin da'irar maganadisu na lantarki, rage jikewar sulke na ƙarfe, rage zub da jini na maganadisu, da samar da ƙarfin filin a cikin rami mai rarrabewa.

◎M-liquid-gas fasahar rabuwa na matakai uku: Abubuwan da ke cikin ɗakin rabuwa suna ƙarƙashin buoyancy, nauyi na kansa, da ƙarfin maganadisu don cimma tasirin fa'ida mai dacewa a ƙarƙashin yanayin da ya dace. Haɗin ruwan saukar da ruwa da hawan iska yana sa matsakaicin tsaftataccen ruwa mai tsabta.

◎Sabuwar spiky bakin maganadisu conductive da Magnetic kayan fasaha: matsakaicin rarrabawa yana ɗaukar ulu na ƙarfe, raga mai siffa mai lu'u-lu'u, ko haɗin ulun ƙarfe da ragar kafofin watsa labarai mai siffar lu'u-lu'u. Wannan matsakaici ya haɗu da halaye na kayan aiki, da bincike da haɓaka haɓakar lalacewa mai ƙarfi mai ƙarfi bakin ƙarfe mai ƙarfi, ƙwanƙolin magnetic filin induction gradient yana da girma, yana da sauƙin kama ma'adanai masu ƙarfi da ƙarfi, ragowar ƙananan ne, kuma matsakaici shine matsakaici. saukin wankewa idan aka sauke takin.

1.3 Binciken ƙa'idar kayan aiki da nazarin rarraba filin maganadisu

1.3.1Ka'idar rarraba ita ce: A cikin coil ɗin sulke, an sanya wani takamaiman adadin ulu na bakin karfe (ko faɗaɗa ƙarfe). Bayan nada yana zumudi, sai ulun bakin karfen da ke yin maganadisu yana yin maganadisu, sannan kuma ana samun filin maganadisu mai ma'ana sosai a saman, wato High-gradient magnetizing magnetic field, lokacin da paramagnetic abu ya ratsa ta cikin ulun karfen da ke cikin tankin rarrabawa, shi. za a sami ƙarfin filin maganadisu daidai da samfurin filin maganadisu da aka yi amfani da shi da kuma ƙarfin filin maganadisu, kuma za a sanya shi a saman ulun ƙarfe, maimakon abin da ba na maganadisu ba ya wuce filin maganadisu kai tsaye. Yana gudana cikin tankin samfurin da ba na maganadisu ba ta hanyar bawul ɗin da ba na maganadisu da bututun mai ba. Lokacin da ƙarancin maganadisu mai rauni da ulun ƙarfe ya tattara ya kai wani matakin (ƙayyade ta hanyar buƙatun tsari), dakatar da ciyar da ma'adinai. Cire haɗin wutar lantarki mai jan hankali kuma ka watsar da abubuwan maganadisu. Abubuwan maganadisu suna gudana cikin tankin samfurin maganadisu ta hanyar bawul ɗin maganadisu da bututun mai. Sannan aiwatar da aikin gida na biyu, kuma maimaita wannan sake zagayowar.

1.3.2Binciken rarraba filin Magnetic: Yi amfani da software na ci gaba mai iyaka don daidaita taswirar rarraba filin maganadisu da sauri, gajarta zagayowar ƙira da bincike; ɗauki ingantaccen ƙira don rage yawan amfani da wutar lantarki da rage farashin mai amfani; gano yuwuwar matsalolin kafin masana'anta samfur , Ƙara amincin samfuran da ayyukan; kwaikwayi tsarin gwaji daban-daban, rage lokacin gwaji da kashe kuɗi;

Halayen motsi na ma'adinai

2.1 Binciken motsi na kayan abu

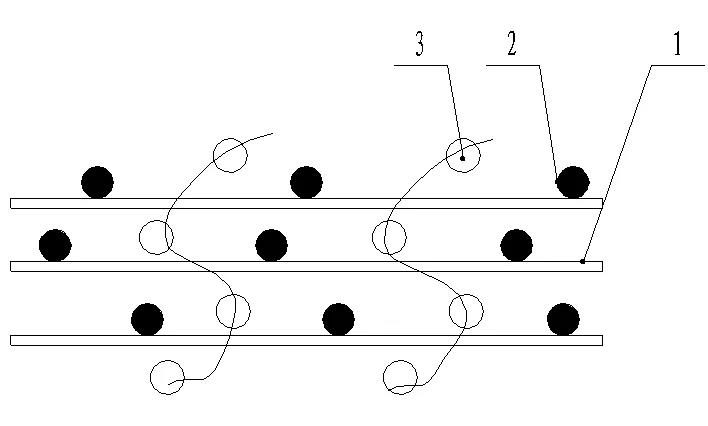

HTDZ babban gradient Magnetic SEPARATOR ya dace da ƙananan ciyarwa lokacin rarraba kaolin. Kayan aiki yana ɗaukar ulun bakin karfe mai nau'i-nau'i mai yawa (ko faɗaɗa ƙarfe) azaman matsakaicin rarrabuwa, ta yadda yanayin ɓangarorin tama ba daidai ba ne a cikin kwatancen tsaye da kwance. An nuna motsin motsi na ma'adinan ma'adinai a cikin Hoto 1. Saboda haka, ƙaddamar da lokacin gudu da nisa na ma'adanai a cikin yanki na rabuwa yana taimakawa ga cikakken adsorption na ƙananan maganadisu. Bugu da kari, slurry kwarara rate, nauyi da buoyancy a lokacin da rabuwa tsari hulda da juna. Tasirin shine a kiyaye barbashi na ma'adinai a cikin sako-sako da kullun, rage mannewa tsakanin barbashi tama, da inganta ingantaccen cire ƙarfe. Samun sakamako mai kyau na rarrabewa.

Hoto 4 Tsarin tsari na motsin ma'adinai

1. Media Network 2. Magnetic particles 3. Marasa maganadisu.

2. Halin danyen tama da kuma ainihin tsari na amfana

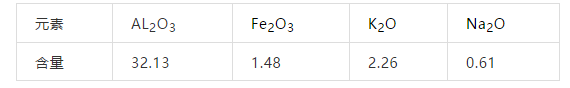

2.1 Abubuwan da ke cikin wasu kayan ma'adinai na kaolin a Guangdong:

Ma'adinan gangue na kaolin a wani yanki a Guangdong sun haɗa da ma'adini, muscovite, biotite da feldspar, da kuma ɗan ƙaramin ja da limonite. Ma'adini ya fi dacewa a cikin nau'in hatsi na + 0.057mm, abun ciki na mica da feldspar ma'adanai an wadatar da su a cikin girman hatsi na tsakiya (0.02-0.6mm), kuma abun ciki na kaolinite da ƙananan ƙananan ma'adanai masu duhu a hankali suna karuwa yayin da hatsi ya karu. girman yana raguwa. , Kaolinite ya fara haɓakawa a -0.057mm, kuma a fili yana wadatar da girman -0.020mm.

Tebur 1 Sakamakon bincike mai yawa na kaolin ore%

2.2 Babban sharuɗɗan fa'ida waɗanda suka dace don binciken gwaji na ƙaramin samfurin

Babban abubuwan da ke shafar tsarin rabuwar maganadisu na HTDZ high gradient slurry Magnetic SEPARATOR su ne slurry kwarara rate, bangon maganadisu ƙarfi, da dai sauransu. Wadannan biyu main yanayi ana gwada a cikin wannan gwaji binciken.

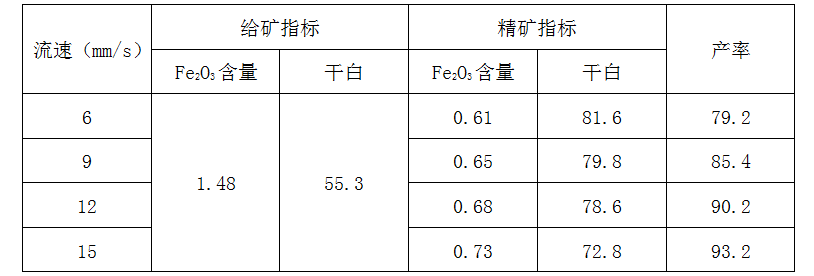

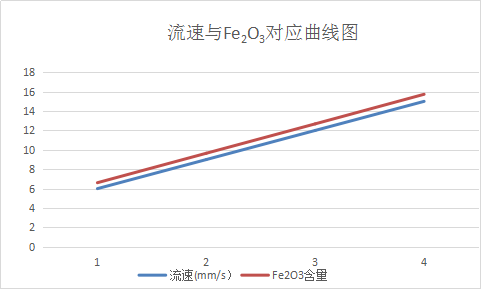

2.2.1 Yawan kwararar ruwa: Lokacin da yawan kwararar ruwa ya yi girma, yawan abin da ake samu ya fi girma, kuma abun da ke cikin baƙin ƙarfe ma yana da yawa; lokacin da yawan kwarara ya yi ƙasa, abun da ke tattare da baƙin ƙarfe yana da ƙasa kaɗan, kuma yawan amfanin sa ma kaɗan ne. Ana nuna bayanan gwaji a cikin Tebura 2

Tebura 2 Sakamakon gwaji na yawan kwararar slurry

Lura: Ana yin gwajin ƙimar kwararar slurry a ƙarƙashin yanayin filin maganadisu na baya na 1.25T da nau'in watsawa na 0.25%.

Hoto 5 Daidaitawa tsakanin adadin kwarara da Fe2O3

Hoto 6 Daidaituwa tsakanin saurin gudu da busasshiyar fari.

Idan aka yi la'akari da ƙimar fa'ida gabaɗaya, yakamata a sarrafa ƙimar slurry a 12mm/s.

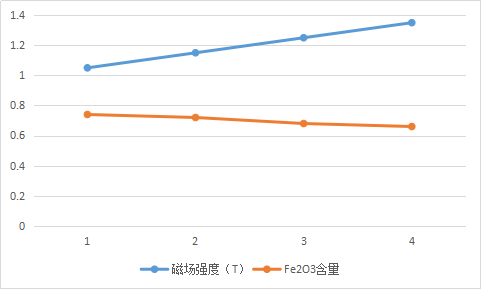

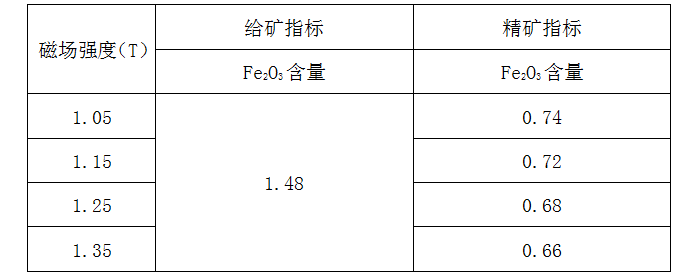

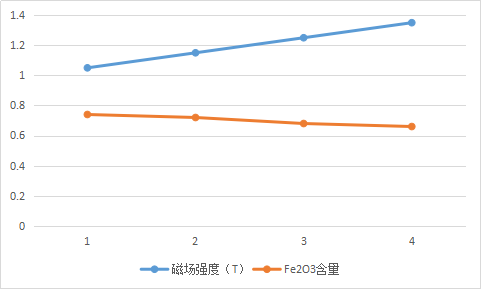

2.2.2 Filin maganadisu na bango: Ƙarfin filin maganadisu na baya na slurry Magnetic SEPARATOR ya yi daidai da ka'idar kawar da ƙarfe na kaolin magnetic rabuwa, wato, lokacin da ƙarfin filin maganadisu ya yi girma, yawan yawan amfanin ƙasa da abun ciki na baƙin ƙarfe da Magnetic SEPARATOR ne duka low, da baƙin ƙarfe kau kudi ne in mun gwada da low. Babban, sakamako mai kyau na cire ƙarfe.

Tebura 3 Sakamakon gwaji na filin maganadisu na baya

Lura: Ana yin gwajin filin maganadisu na bango a ƙarƙashin yanayin ɗimbin kwararar slurry na 12mm/s da adadin watsawa na 0.25%.

Saboda mafi girman girman filin maganadisu na baya, mafi girman ƙarfin motsa jiki, mafi girman yawan kuzarin kayan aiki, kuma mafi girman farashin samar da naúrar. Idan aka yi la'akari da farashin fa'ida, an saita filin maganadisu da aka zaɓa a 1.25T.

Hoto 7 Daidaituwa tsakanin ƙarfin filin maganadisu da abun ciki na Fe2O3.

2.3 Zaɓin zaɓi na asali na magnetic rabuwa

Babban manufar amfanar kaolin tama shine don cire ƙarfe da tsarkakewa. Dangane da bambancin maganadisu na kowane ma'adinai, yin amfani da babban filin maganadisu don cire baƙin ƙarfe da tsarkake kaolin yana da tasiri, kuma tsarin yana da sauƙi da sauƙin aiwatarwa a cikin masana'antu. Don haka, ana amfani da babban mai slurry slurry Magnetic Separator, ɗaya m kuma ɗaya mai kyau, azaman tsari na rarrabuwa.

Samar da masana'antu

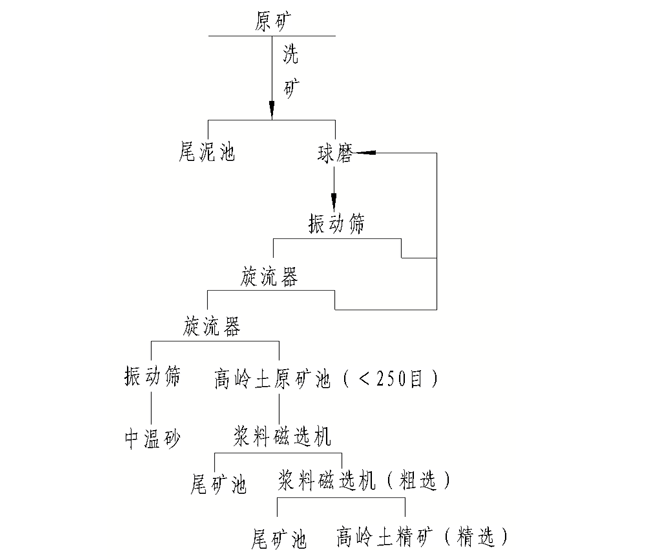

3.1 Kaolin tsarin samar da masana'antu

Don cire baƙin ƙarfe daga kaolin tama a wani yanki a cikin Guangdong, ana amfani da jerin haɗin HTDZ-1000 don samar da tsarin rabuwar maganadisu mara kyau. Ana nuna ginshiƙi mai gudana a hoto na 2.

3.2 Yanayin samar da masana'antu

3.2.1Rarraba kayan abu: babban maƙasudi: 1. Rarrabe ƙazanta irin su ma'adini, feldspar da mica a cikin kaolin a gaba ta hanyar guguwa mai matakai biyu, rage matsa lamba na kayan aiki na gaba, da kuma rarraba girman ƙwayar don saduwa da bukatun kayan aiki na gaba. 2. Tun da rabuwa matsakaici na slurry Magnetic SEPARATOR ne 3 # karfe ulu, da barbashi size dole ne a kasa 250 raga don tabbatar da cewa babu barbashi saura a cikin karfe ulu matsakaici don hana karfe ulu matsakaici toshe karfe ulu matsakaicin. , yana shafar ma'anar fa'ida da matsakaicin wankewa Da ikon sarrafa kayan aiki, da dai sauransu.

3.2.2Yanayin aiki na rabuwar maganadisu: tsarin tafiyar da tsarin yana ɗaukar nau'i mai mahimmanci da gwaji mai kyau guda ɗaya da kuma tsari ɗaya mai kyau da kuma tsari mai kyau na budewa. Dangane da gwajin samfurin, ƙarfin filin bango na babban gradient slurry Magnetic SEPARATOR don roughing aiki shine 0.7T, babban gradient Magnetic SEPARATOR don aikin zaɓi shine 1.25T, kuma ana amfani da HTDZ-1000 Magnetic SEPARATOR don roughing slurry. . Sanye take da wani HTDZ-1000 zaba slurry Magnetic SEPARATOR.

3.3 Sakamakon samar da masana'antu

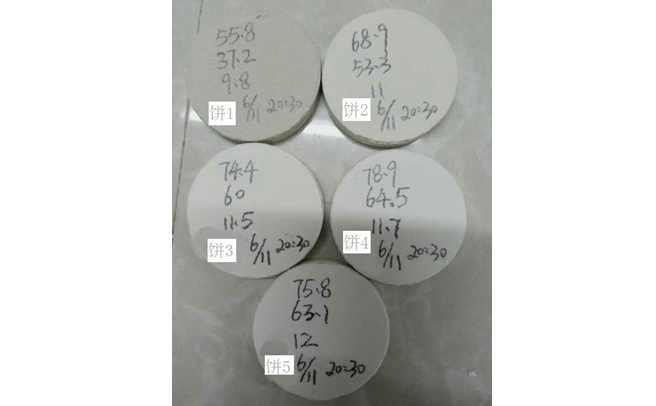

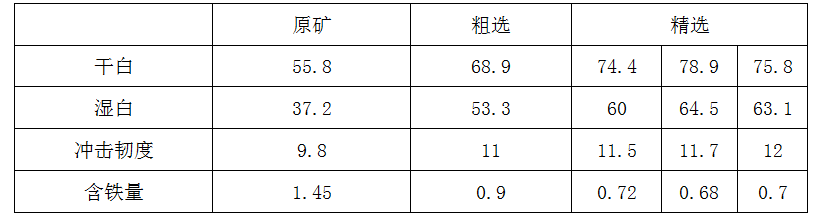

Samfurin masana'antu na kaolin don cire baƙin ƙarfe a wani wuri a cikin Guangdong, samfurin samfurin samfurin da HTDZ slurry high gradient Magnetic SEPARATOR aka nuna a cikin Hoto 3, da kuma bayanai da aka nuna a cikin Table 2.

Cake 1: Cake ne mai ɗanyen tama wanda ke shiga cikin madaidaicin rabuwar slurry magnetic SEPARATOR

Pie 2: Kimanin zaɓaɓɓen samfurin kek

Kek 3, Kek 4, Kek 5: Samfuran da aka zaɓa

Tebur 2 Sakamakon samar da masana'antu (sakamakon samfuri da karya biredi a 20:30 ranar 6 ga Nuwamba)

Hoto na 3 Wani samfurin wainar da kaolin ya samar a wani wuri a Guangdong

Sakamakon samarwa ya nuna cewa Fe2O3 abun ciki na mai da hankali za a iya rage da game da 50% ta biyu high-gradient Magnetic rabuwa na slurry, kuma za a iya samu mai kyau iron cire sakamako.

应用案例

Lokacin aikawa: Maris 27-2021