Sakamakon karancin makamashi a duniya, yawan makamashin da ake amfani da shi a cikin tsarin murkushewa ya fi jawo hankali. Tun bayan zuwan injin nadi mai tsananin matsin lamba a ƙarshen shekarun 1980, an fi amfani da shi a masana'antar siminti da ma'adinan ƙarfe waɗanda ba na ƙarfe ba. Masana'antar siminti sun amfana da wannan kayan aiki masu inganci waɗanda ke adana makamashi da ƙarfe.

Adadin dakakkiyar karafa da ma'adinai na da yawa, kuma galibin takin karfen suna da wuyar nika. A halin yanzu, matsalolin da ake amfani da su na makamashi, amfani da karfe da kuma ingancin injinan ƙwallon ƙafa sun yi fice sosai, kuma hanyar niƙan ma'adinan ma yana tasiri sosai. The high matsa lamba nadi niƙa ne yadu amfani a karafa da kuma ma'adinai masana'antu, kuma shi ne a kan manyan matakin a duniya. Sakamakon bincike da ayyukan masana'antun cikin gida da aka yi a cikin 'yan shekarun nan, da kuma nasarar karshe.

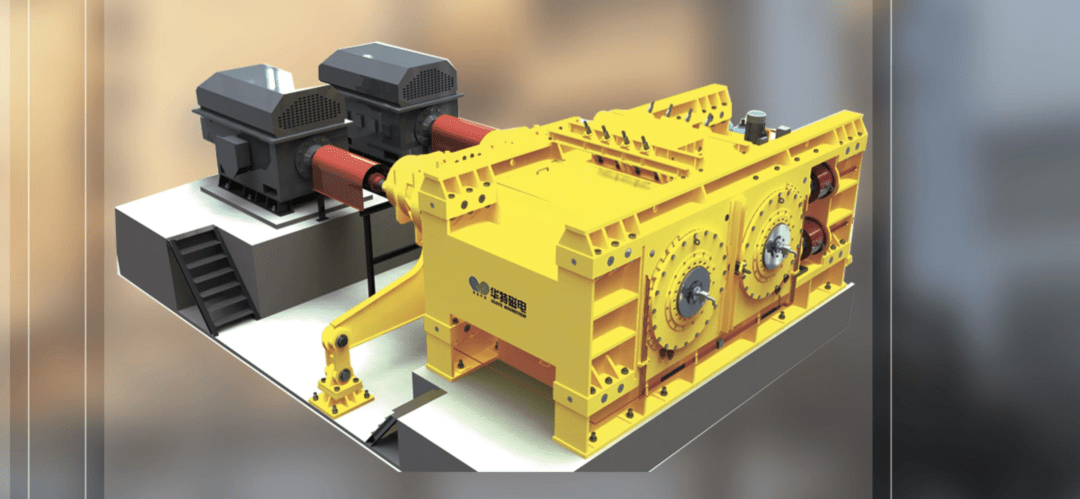

Halayen Fasaha na HUATE HPGM Babban Matsi na Roller Mill

HUATE MAGNET

Bambanci tsakanin babban matsi na abin nadi da kayan murkushe gargajiya

Babban injin abin nadi ya yi kama da na gargajiya biyu na nadi, amma akwai bambance-bambancen asali guda biyu.

Ɗaya shi ne cewa injin na'ura mai ƙarfi yana aiwatar da murkushewar ƙima, wanda ke adana kusan 30% na amfani da makamashi idan aka kwatanta da murkushe tasiri;

Na biyu, yana aiwatar da murkushe kayan abu don kayan, wanda shine murkushe juna tsakanin kayan aiki da kayan aiki, tare da haɓakar haɓakar haɓakawa, kuma za'a iya daidaita damuwa mai tsauri tsakanin kayan ta hanyar matsa lamba. Rollers guda biyu suna jujjuyawa gaba da juna, ɗayan ƙayyadaddun abin nadi ne ɗayan kuma nisa mai daidaitacce. Matsakaicin da ke tsakanin rollers na iya kaiwa 1500 zuwa 3000 yanayi gabaɗaya, kuma samfuran da aka murkushe na iya kaiwa 2mm, wanda ya fahimci "ƙarin murƙushewa da ƙarancin niƙa" kuma ya zama sabon nau'in murkushe kayan aikin da ke maye gurbin niƙa tare da murƙushewa. Saboda ƙarfinsa mai ƙarfi, ba wai kawai ya rushe kayan ba, amma har ma yana lalata tsarin ciki na kayan aiki, don haka yana inganta ƙarfin nika.

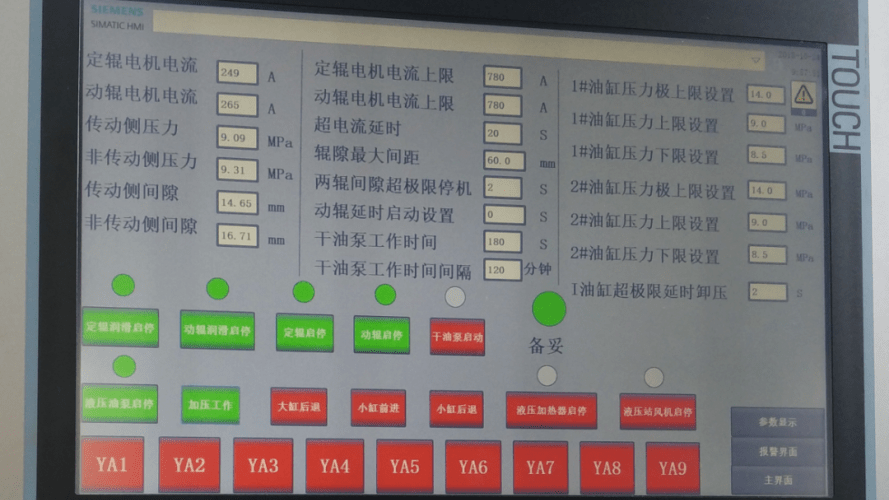

Babban matsi na abin nadi ya ƙunshi na'urar ciyar da lantarki, na'urar toshe kayan, na'urar tuki, na'urar ɗora ruwa, na'urar tallafi, sassauƙan abubuwan abin nadi, da dai sauransu.

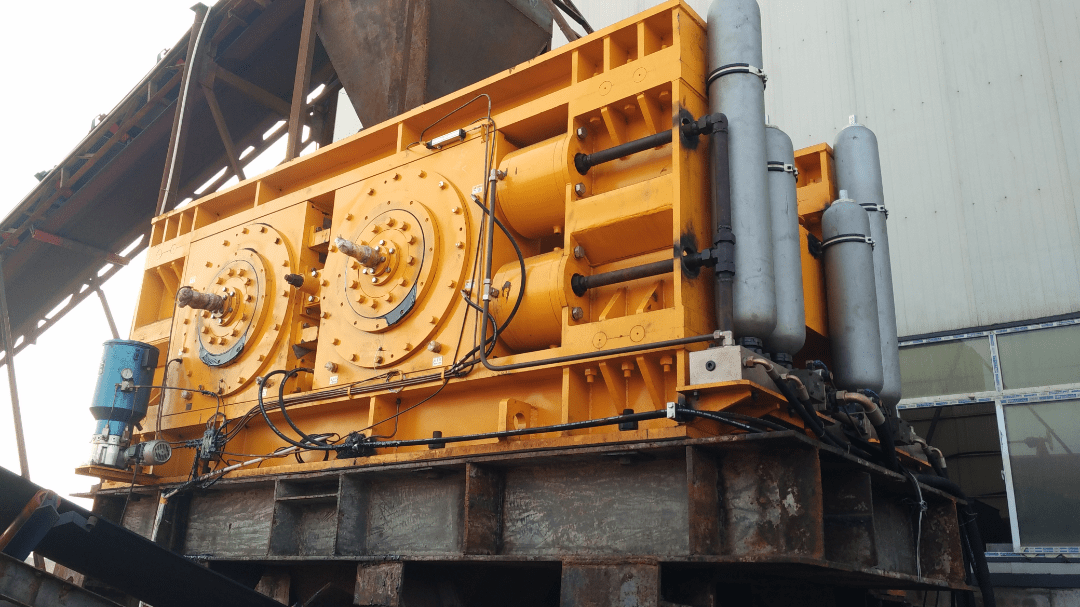

Wurin aiki na HUATE HPGM babban matsi na abin nadi

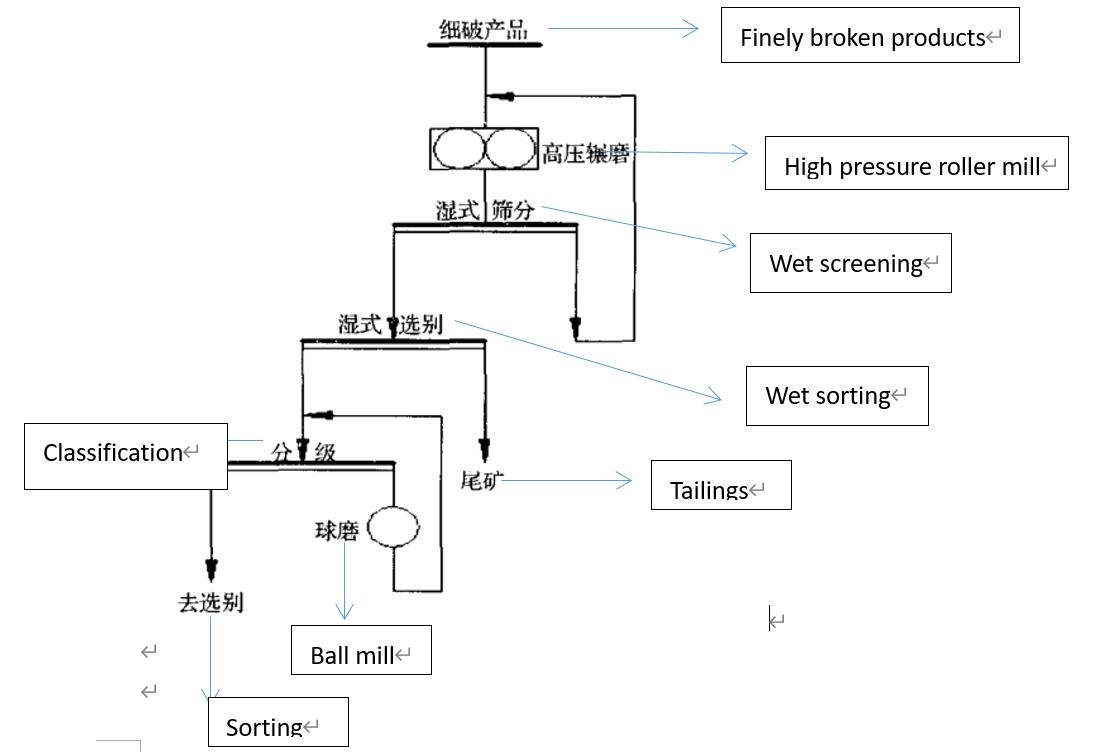

Hannun tsari kwarara na babban matsa lamba nadi niƙa a fa'ida

1. M hatsi rufaffiyar-kewaye abin nadi niƙa rigar wutsiya aiwatar jifa

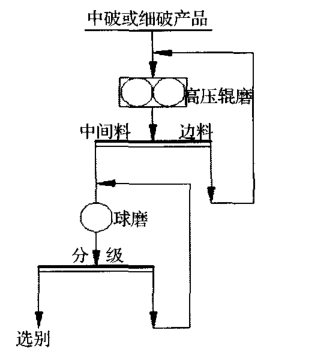

A cikin tsarin yin amfani da wannan injin don sarrafa tama, jigon wutsiya na jifar daɗaɗɗen abin nadi mai rufaffiyar-dawafi tsari ne na gama gari. Hoton da ke gaba yana nuna babban tsarin gudana:

M hatsi rufaffiyar-kewaye abin nadi niƙa rigar wutsiya jifa tsari kwarara ginshiƙi

A cikin takamaiman aikace-aikacen wannan tsari, cake ɗin abrasive yana nunawa ta hanyar rufaffiyar da'ira, ta yadda girman barbashi na samfurin da injin nadi mai ƙarfi zai iya sarrafa shi koyaushe a cikin kewayon da ya dace sosai don rarrabawa da wutsiya. , kuma a ƙarshe cimma manufar pre-jefa wutsiya.

1. Sashe na ball aikin niƙa tsari na rufaffiyar-circuit abin nadi

Ta hanyar babban adadin ayyukan samarwa da gwaje-gwaje masu alaƙa, an gano cewa samfuran tama da aka samu ta hanyar injin abin nadi mai ƙarfi ba wai kawai suna da girman ƙwayar ƙwayar cuta ba, amma har ma sun sami ƙaruwa mai yawa a cikin abun ciki na foda na ma'adinai. Daga cikin su, abun ciki na kayan cikin 0.2mm na iya kaiwa 30% -40%, kayan wannan matakin fineness na iya saduwa da buƙatun rarrabuwa a mafi yawan lokuta, don haka don irin wannan samfurin, ana iya aiwatar da aikin rarraba kai tsaye bayan rarraba shi.

A lokaci guda, a kan aiwatar da yin amfani da high-matsi nadi niƙa ga tama beneficiation da tama crushing samar, a karkashin mataki na gefen abu sakamako, za a yi wani karamin sashi na tama barbashi da wuce kima barbashi size a cikin extrusion cake. Idan an yi amfani da wannan ɓangaren kai tsaye Yayin aikin niƙa ko amfanuwa, madaidaicin aikin aikin zai canza sosai, wanda zai kawo wani ɗan ƙaramin tasiri akan samar da fa'ida.

Sabili da haka, a cikin aiwatar da samar da fa'ida ta kayan aikin injiniya, don guje wa irin waɗannan matsalolin, dole ne a gudanar da aikin rufewar kewayon kek ɗin kayan bayan aikin extrusion ta hanyar injin nadi mai ƙarfi. Ta wannan hanyar, girman barbashi na samfurin a cikin kek za a iya sarrafa shi sosai don hana canjin tsarin da ya haifar da shigowar tama tare da girman girman barbashi cikin aikin milling na ƙwallon. Kuma sanya shi kai tsaye cikin tsarin zaɓin. Irin wannan hanya ba wai kawai za ta iya cimma gagarumin raguwar yawan ciyar da tama a cikin tsarin niƙa ƙwallon ƙafa ba, amma kuma yadda ya kamata a guje wa niƙa na ma'adanai masu kyau, ta haka ne ke haɓaka inganci da ingancin fa'ida.

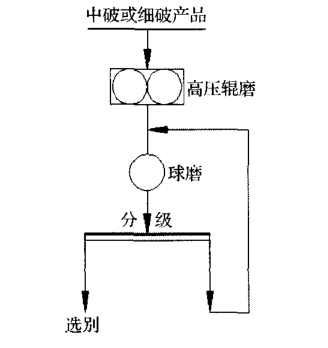

3 Wasu nau'i na hankula tsari kwarara tsari

Baya ga matakai biyu na sama da aka fi amfani da su, akwai wasu matakai na yau da kullun na yau da kullun a cikin murkushewa da tsarin samar da fa'ida ta ma'adinan abin nadi. Ɗayan shine buɗaɗɗen abin nadi niƙa ball niƙa a cikin nau'i na cikakken nau'i na girman nau'in fasaha.

Bude-da'irar abin nadi niƙa ball niƙa tsari kwarara ginshiƙi

Sauran shine tsarin milling na ball a cikin nau'i na abin nadi na niƙa edging abu wurare dabam dabam. Mai zuwa shine babban ginshiƙi mai gudana:

Flow ginshiƙi na ball milling tsari a cikin nau'i na nadi nika gefen abu wurare dabam dabam

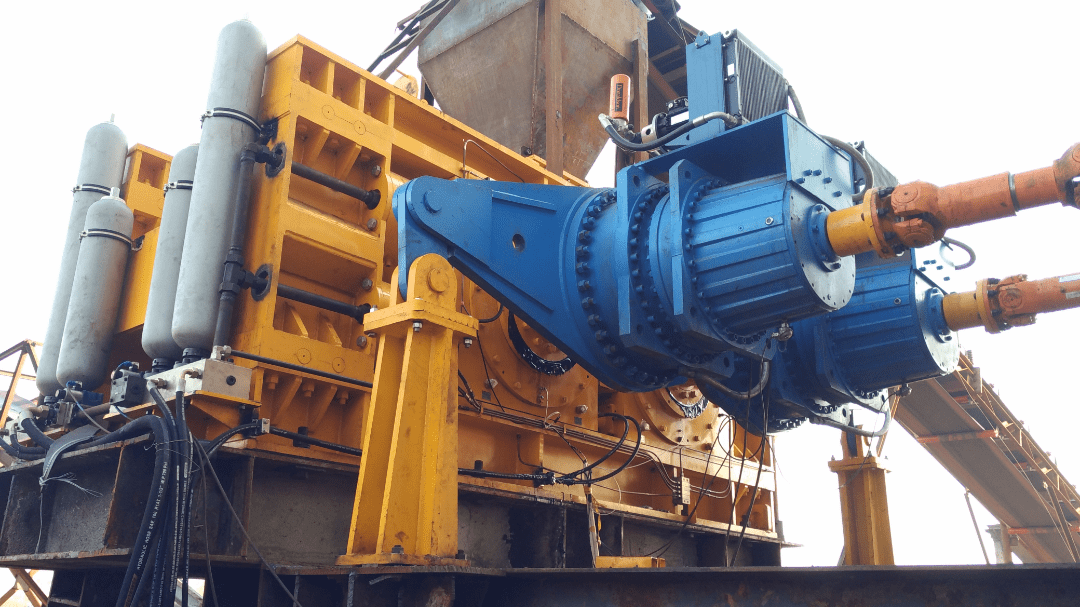

Misalin aikace-aikacen HUATE HPGM babban matsi na abin nadi

Ana amfani da injin nadi mai ƙarfi na HPGM1480 a cikin babban mai da hankali a Arewacin China

Lokacin aikawa: Jul-11-2022