Ma'adinan ƙarfe na ƙasarmu yana da wadataccen tanadi da nau'ikan iri, amma akwai ma'adanai masu yawa da yawa, 'yan ma'adanai masu yawa, da ƙaƙƙarfan ƙorafi. Akwai 'yan ma'adanai waɗanda za a iya amfani da su kai tsaye. Ana buƙatar sarrafa yawan adadin ma'adinai kafin a iya amfani da su.Na dogon lokaci, an sami samun riba mai wuyar gaske a tsakanin zaɓaɓɓun ma'adinan da aka zaɓa, rabon fa'ida ya zama babba kuma ya fi girma, tsari da kayan aiki sun zama ƙari kuma mafi hadaddun, musamman kudin nika ya nuna wani karuwa Trend. A halin yanzu, masana'antun sarrafa gaba daya daukar matakai kamar kara murkushe da rage nika, da pre-zaba da zubar da sharar gida kafin nika, wanda ya samu gagarumin sakamako.

Gabaɗaya magana, bushewar jifa before niƙa ya fi fa'ida a cikin yanayi mai zuwaakan:

(1) Inyankunaninda albarkatun ruwa ba su da yawa, ba za a iya tabbatar da ruwa don ci gaban hakar ma'adinai ba, wanda hakan ya sa yuwuwar rabuwar ma'adinan jika ba ta da yawa. Sabili da haka, a cikin waɗannan wuraren, za a fara la'akari da busassun hanyoyin zaɓe kafin zaɓe.

(2) Wajibi ne don rage yawan slurry na wutsiya da rage matsa lamba na kandami. Za a ba da fifiko ga bushewa kafin zaɓe da zubar da shara.

(3) Busasshiyar jifa da manyan tama ya fi dacewa fiye da rabuwar ruwa.

(4) Busasshiyar jifa ana raba ta zuwa matakai da yawa:

Busassun jifa na samfuran da aka niƙa da su tare da matsakaicin girman barbashi 400~125 mm, bushe polishing na matsakaici-murkushe kayayyakin da matsakaicin barbashi size of 100-50 mm, Fine murkushe da bushe polishing tare da matsakaicin barbashi size of 25~5 mm, kazalika da bushe polishing na crushed kayayyakin da high-matsa lamba nadi Mills, wanda a halin yanzu ana amfani da ko'ina, da tsarin na zaba kayan aiki ne daban-daban.

Busassun kayan aikin rabuwa don kayan tare da matsakaicin girman barbashi na 20 mm ko fiye

Domin bushe polishing na tama tare da matsakaicin barbashi size of 20 mm ko fiye, da CTDG jerin m maganadisu bushe girma Magnetic SEPARATOR ne a halin yanzu mafi yadu amfani.

Dindindin magnet bushe girma Magnetic separators ana amfani da ko'ina a karfe ma'adinai da sauran masana'antu don saduwa da manyan, matsakaita da kuma kananan ma'adanai. Ana amfani da su don zaɓin kayan da aka riga aka zaɓa tare da matsakaicin girman ƙwayar ƙwayar cuta ba fiye da 500 mm ba bayan murkushewa a cikin injin rabuwar magnetic. Don dawo da darajar yanayin ƙasa na dutsen sharar gida, zai iya adana makamashi da rage yawan amfani, da haɓaka ƙarfin sarrafawa na masana'antar sarrafawa; Ana amfani da shi a cikin tasha don dawo da ma'adinan magnetite daga dutsen sharar gida don haɓaka ƙimar amfani da albarkatun tama; ana amfani da shi don dawo da ƙarfe na ƙarfe daga karfen karfe; ana amfani da shi wajen zubar da shara don ware karafa masu amfani.

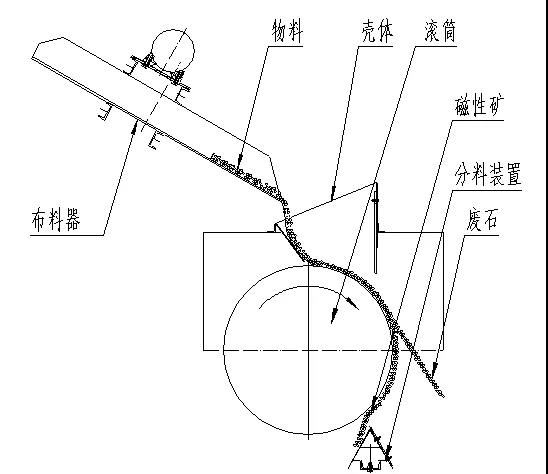

Dindindin magnet bushe girma Magnetic SEPARATOR yafi amfani da Magnetic ƙarfi ga rabuwa, The ma'adinai ne a ko'ina ciyar da bel da hawa zuwa jerawa yankin a kan babba ɓangare na Magnetic drum a akai speed.A karkashin mataki na Magnetic karfi, da karfi Magnetic ƙarfi. Ana sanya ma'adanai a saman bel ɗin ganga na maganadisu, suna gudu zuwa ƙananan ɓangaren ganga kuma su rabu da filin maganadisu, kuma suna faɗa cikin tanki mai ƙarfi da nauyi. Ƙarfin maganadisu ba zai iya jan hankalin dutsen sharar gida da tama mai rauni mai ƙarfi ba kuma su kula da rashin aiki. Aka jefe shi da kyau a gaban partitioning partition ya fada cikin kwandon wutsiya.

Daga cikin ra'ayi na tsarin, da m maganadisu bushe girma Magnetic SEPARATOR yafi hada da drive mota, na roba fil hada guda biyu, drive reducer, giciye slide hada guda biyu, Magnetic drum taro da Magnetic daidaita reducer.

Abubuwan fasaha na tsari

(1) Don busassun busassun samfuran da aka murkushe tare da matsakaicin girman ƙwayar 400-125 mm. Saboda girman tama mai girma, bel ɗin yana isar da adadi mai yawa bayan murƙushewa, kuma ɓangaren sama na mai ɗaukar bel ɗin ya shiga wurin rarraba ganga. Don cimma sakamako mai ma'ana da zubar da sharar gida da rage abun ciki na baƙin ƙarfe na wutsiya, Magnetic drum a wannan mataki yana buƙatar samun zurfin shigar da magnetic ya fi girma, ta yadda za a iya kama manyan barbashi na tama.Mahimman wuraren fasaha na tsarin samfurin a wannan mataki: ① Mafi girman diamita na nadi, mafi kyau, yawanci har zuwa 1. 400 mm ko 1 500 mm. ② Faɗin bel yana da faɗi sosai. Matsakaicin girman ƙira na bel ɗin da aka zaɓa a halin yanzu shine 3 000 mm; bel ɗin yana da tsayi gwargwadon yiwuwa a cikin madaidaiciyar sashe kusa da kan drum, don haka Layer ɗin kayan da ke shiga wurin ya zama bakin ciki. Ɗauki nau'in ɓangarorin tama tare da matsakaicin girman barbashi na 300-400 mm a matsayin misali. Gabaɗaya, ƙarfin filin maganadisu a nesa na 150-200 mm daga saman drum daga wurin tsotsa drum zuwa saman ganga ya fi 64kA / m, kamar yadda aka nuna a cikin Hoto 1. 1.④ Rata tsakanin farantin rarraba da drum ya fi 400 mm kuma yana daidaitawa. ⑤ Gudun aiki na drum yana daidaitacce, kuma daidaitawar kusurwar raguwar maganadisu da daidaitawar na'urar rarrabawa ya sa ma'anar rarrabawa mafi kyau.

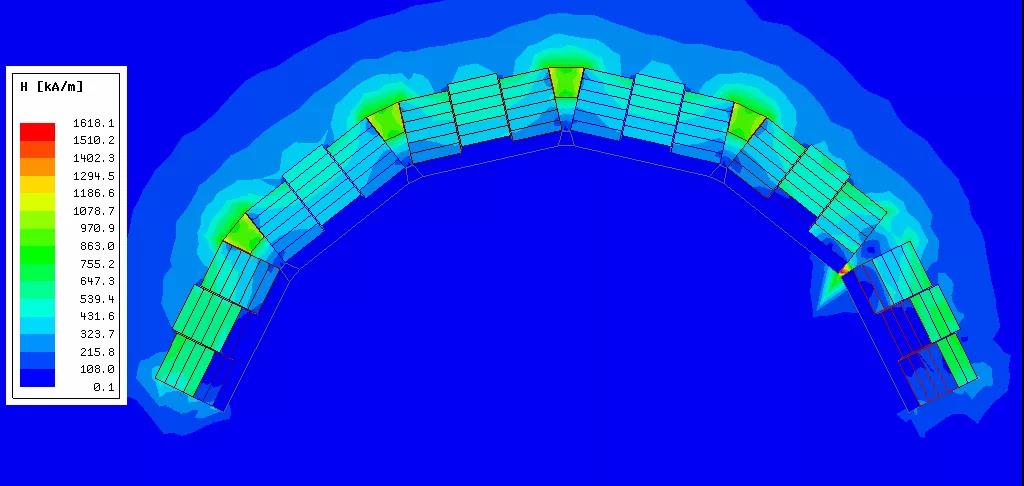

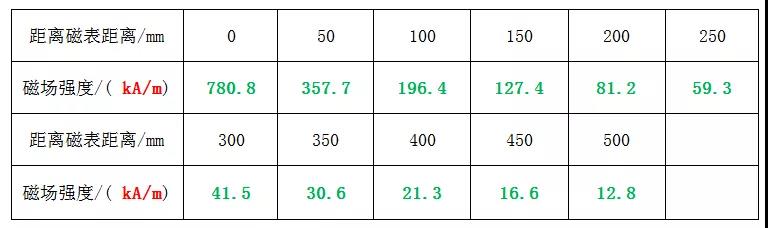

Hoto 1 Taswirar girgije na filin Magnetic

Tebura 1 Ƙarfin filin Magnetic a wani tazara daga teburin maganadisu kA/m

Ana iya gani daga tebur 1 cewa ƙarfin filin maganadisu a nesa na 200 mm daga saman tsarin maganadisu shine 81.2 kA/m, kuma ƙarfin filin maganadisu a nesa na 400 mm daga saman tsarin maganadisu. 21.3 kA/m.

(2) Domin bushe polishing na matsakaici crushed kayayyakin tare da iyakar barbashi size of 100-50 mm, saboda finer barbashi size da thinner abu Layer, zane sigogi da m murkushe bushe selection za a iya gyara daidai:①Diamita na ganga yawanci 1 000, 1 200, 1 400 mm.②Girman bel ɗin da aka saba shine 1 400, 1 600, 1 800, 2 000 mm; bel ɗin yana da tsayin tsayin daka a cikin madaidaiciyar sashe kusa da kan drum, don haka Layer kayan da ke shiga wurin rarraba ya ragu.③Girman zurfin shiga cikin maganadisu, ɗaukar nau'in ɓangarorin tama tare da matsakaicin girman 100 mm a matsayin misali, yawanci ƙarfin filin maganadisu a nesa na 100-50 mm daga saman drum daga yankin tsotsa drum zuwa saman drum. fiye da 64kA/m, kamar yadda aka nuna a Figure 2 da Table 2.④Rata tsakanin farantin rarraba da drum ya fi 100 mm kuma yana daidaitawa.⑤Gudun aiki na drum yana daidaitacce, kuma daidaitawar kusurwar raguwar maganadisu da daidaitawa na na'urar rarrabawa yana sa ma'anar rarrabawa mafi kyau.

Hoto 2 Taswirar girgije na filin Magnetic

Tebur 2 Ƙarfin filin Magnetic a wani tazara mai nisa daga teburin maganadisu kA/m

Ana iya gani daga tebur na 2 cewa ƙarfin filin maganadisu a nesa na 100 mm daga saman tsarin maganadisu shine 105 kA/m, kuma ƙarfin filin maganadisu a nesa na 200 mm daga saman na'urar. 30.1 kA/m.

(3) Domin bushe polishing na finely raba kayayyakin tare da iyakar barbashi size na 25-5 mm, a karami drum diamita da karami Magnetic zurfin shigar azzakari cikin farji za a iya zaba a cikin zane da zabin, wanda ba za a tattauna a nan.

Kayan aikin bushewa don kayan da matsakaicin girman barbashi ƙasa da 20 mm.

- MCTF jerin pulsating bushe Magnetic SEPARATOR

MCTF jerin pulsating bushe Magnetic SEPARATOR ne matsakaici filin ƙarfi Magnetic rabuwa kayan aiki. Ya dace da ma'adanai masu laushi irin su dutsen dutse, yashi, yashi kogi, yashi na teku, da dai sauransu.~0 mm ku. Matsakaicin ma'adinan maganadisu da busassun pre-zaɓin samfuran magnetite da aka murƙushe.

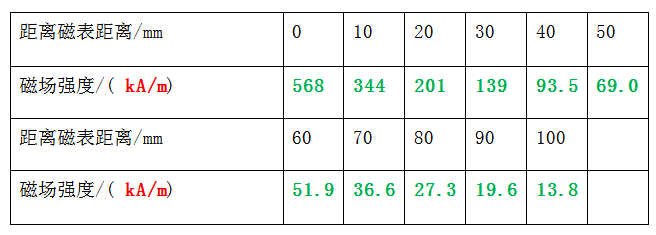

1.2 Ka'idar aiki

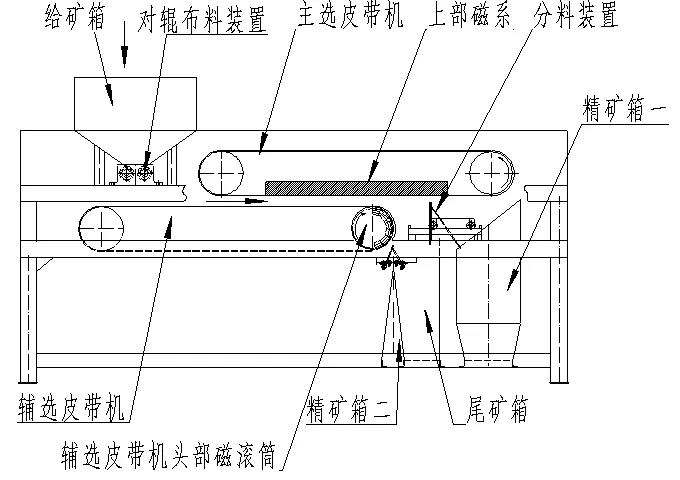

Ka'idar aiki na jerin MCTF mai busassun busassun maganadisu ana nuna su a cikin hoto 3.

Hoto 3 Tsarin tsari na ka'idar aiki na nau'in MCTF mai bugun busasshen maganadisu

Yin amfani da ka'idar cewa kayan maganadisu na iya jawo hankalin abubuwan maganadisu na dindindin, an saita tsarin magnetic semicircular tare da filin maganadisu mafi girma a cikin drum ta hanyar da kayan ke gudana.Lokacin da kayan ke gudana ta cikin filin maganadisu, ana kama ƙwayoyin ma'adinai na Magnetic ta hanyar karfi Magnetic karfi da kuma adsorbed a kan surface na Semi- madauwari Magnetic system.Lokacin da Magnetic ma'adinai barbashi da aka kawo zuwa ga ƙananan da ba Magnetic yankin ta jujjuya drum, sun fada zuwa mayar da hankali kanti da aka sallama a karkashin mataki na nauyi. Non Magnetic tama ko tama tare da ƙananan matakin ƙarfe na iya gudana cikin yardar kaina ta cikin filin maganadisu zuwa kanti na wutsiya ƙarƙashin aikin nauyi da ƙarfin centrifugal.

Daga tsarin ra'ayi, nau'in nau'in MCTF mai bugun busasshen maganadisu ya ƙunshi na'urar daidaita tsarin maganadisu, taron ganga, harsashi na sama, murfin ƙura, firam, na'urar watsawa, da na'urar rarrabawa.

Abubuwan fasaha na tsari

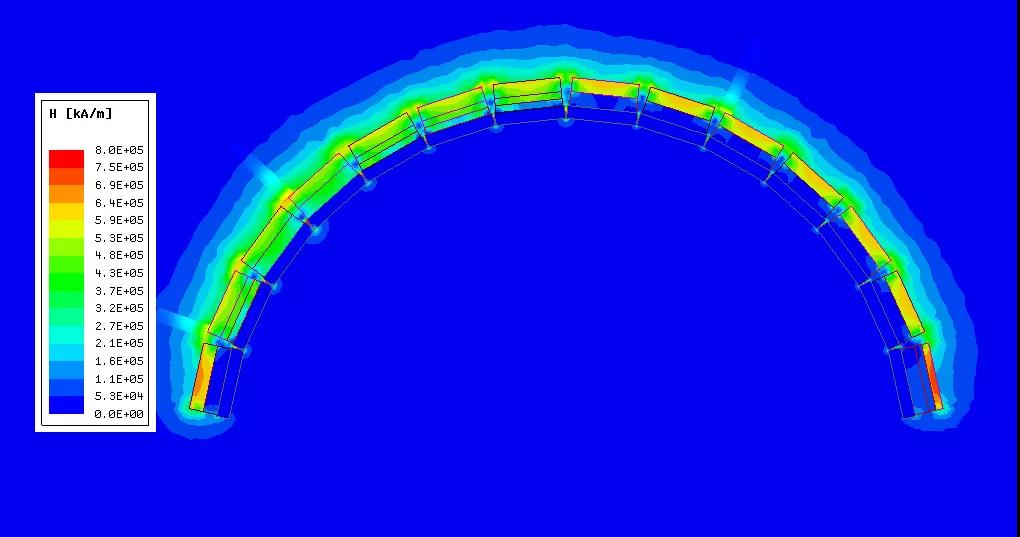

Babban mahimman abubuwan fasaha na tsarin sun haɗa da: ①Maɗaukakin abin nadi da aka saba amfani da su shine 800, 1,000, da 1 200 mm; zane ya bi ka'idar cewa mafi girman girman ƙwayar ya dace da ƙananan diamita, kuma mafi girman girman girman ƙwayar ya dace da girman diamita na drum. ② Tsawon ganga yawanci ana sarrafa shi a cikin 3,000 mm. Idan ganga ya yi tsayi da yawa, rigar ba za ta kasance iri ɗaya ba a tsayin tsayin daka, wanda zai shafi tasirin rarrabawa. adadin igiyoyin magnetic yana ƙaruwa, wanda ya dace da yawan juyawa na kayan aiki kuma ya gane rabuwa da wutsiyoyi masu ladabi na kayan; lokacin da kauri daga cikin Layer Layer shine 30 mm, nisa daga saman drum shine 30 Ƙarfin filin maganadisu a mm shine 64kA / m, duba Hoto 4 da Table 3. mm kuma yana daidaitacce. ⑤ Don tabbatar da rarraba iri ɗaya a cikin tsayin drum, kayan aikin ya kamata a sanye su da kayan taimako irin su chute, mai faɗakarwa, mai rarraba karkace ko mai rarraba tauraro. ciyarwa mai yawa. ⑦ Gudun aiki na drum yana daidaitawa, kuma daidaitawar kusurwar raguwar magnetic da daidaitawar na'urar rarraba kayan aiki ya sa ma'anar rarrabawa mafi kyau. Wurin aikace-aikacen na MCTF mai busasshen maganadisu mai busasshiyar maganadisu tare da mai ba da jijjiga ana nuna shi a hoto na 5.

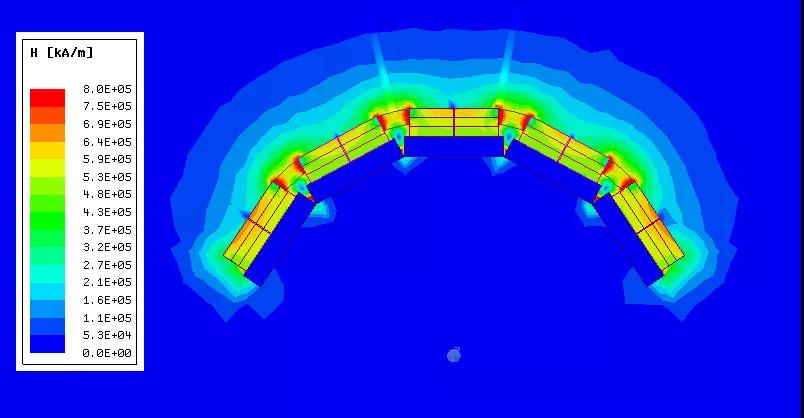

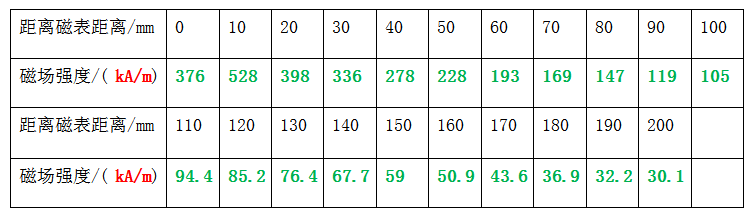

Hoto 4 Taswirar girgije na filin Magnetic

Tebur 3 Ƙarfin filin Magnetic a wani tazara mai nisa daga teburin maganadisu kA/m

Ana iya gani daga tebur na 3 cewa ƙarfin filin maganadisu a nesa na 30 mm daga saman tsarin maganadisu shine 139kA/m, kuma ƙarfin filin maganadisu a nesa na 100 mm daga saman tsarin maganadisu shine 13.8 ka/m.

Hoto 5 Wurin aikace-aikacen MCTF mai busasshen maganadisu mai busasshen maganadisu tare da mai ba da jijjiga

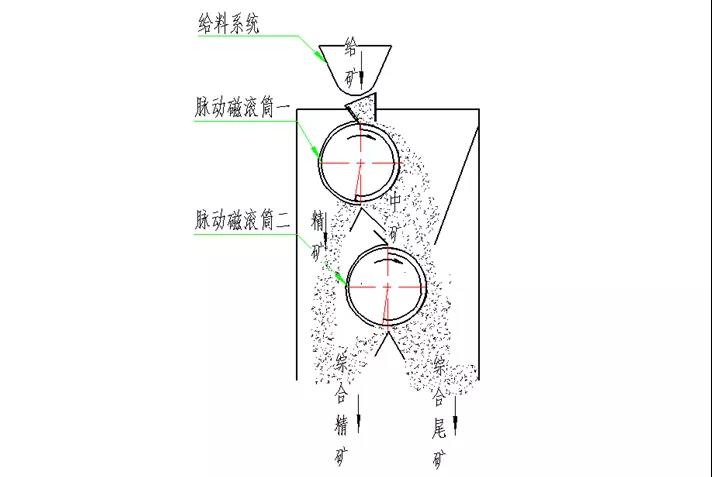

2.MCTF jerin biyu drum pulsating bushe Magnetic SEPARATOR

2.1 Ka'idar aiki na share fage

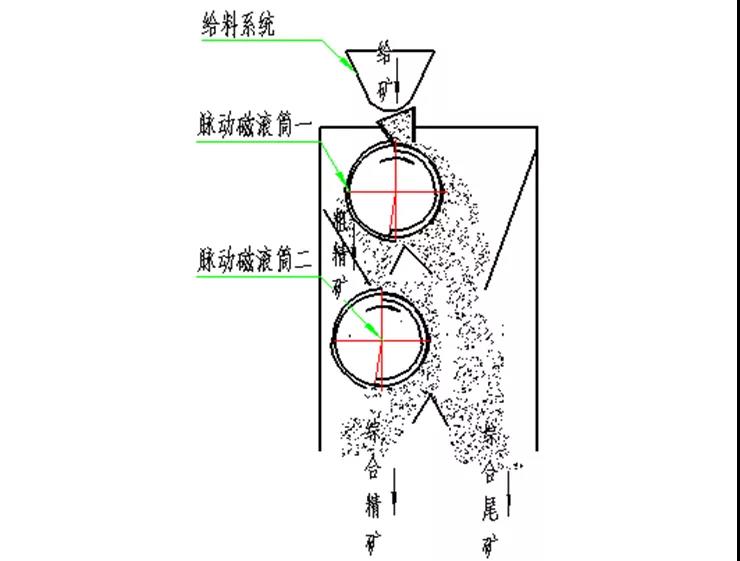

Kayan aiki suna shiga ma'adinan ta na'urar ciyarwa. Bayan an jera ma'adinin ta hanyar ganga na farko, an fara fitar da wani ɓangare na abin da aka tattara. Wutsiyoyi na ganga na farko suna shiga ganga na biyu don sharewa, kuma zazzagewar hankali da na farko suna haɗe don zama taro na ƙarshe. , Wutsiyar da aka zazzage ita ce wutsiya ta ƙarshe. Ana nuna ƙa'idar aiki na share fage guda ɗaya a cikin hoto 6.

2.2 Ka'idar aiki na daya m da daya tara

Kayan aiki suna shiga ma'adinan ta na'urar ciyarwa. Bayan an jera ma'adinan da ganga na farko, an fara jefar da wani ɓangare na wutsiyar. Mahimmancin ganga na farko yana shiga cikin ganga na biyu don zaɓar, kuma na biyu na rarraba ganga shine taro na ƙarshe. Wutsiyoyi na ɗorawa na biyu suna haɗuwa cikin wutsiya ta ƙarshe. An nuna ƙa'idar aiki na ɗaya mai kauri da tara a cikin hoto 7.

Hoto 7 Misali na ka'idar aiki na m da lafiya

Abubuwan fasaha na tsari

Technical maki na 2MCTF jerin biyu drum pulsating bushe Magnetic SEPARATOR: ①Ainihin zane manufa shi ne iri daya da MCTF jerin pulsating bushe Magnetic SEPARATOR. ② Ƙarfin filin maganadisu na bututu na biyu ya fi na bututu na farko lokacin da na farko ya kasance m da sharewar farko; Ƙarfin filin maganadisu na bututu na biyu ya yi ƙasa da bututun farko lokacin da na farko ya kasance m da sauran lafiya. Wurin aikace-aikacen na 2MCTF drum mai busassun busassun maganadisu sanye da na'urar ciyarwa mai siffar tauraro da na'urar aunawa ta atomatik ana nunawa a cikin Hoto 8.

Hoto 8 Wurin aikace-aikacen 2MCTF mai busasshen busasshen maganadisu sanye da na'urar ciyarwa mai siffar tauraro da na'urar aunawa ta atomatik.

3.3MCTF jerin uku-dum pulsating bushe Magnetic SEPARATOR

3.1 Ƙa'idar aiki na ɗaya m da share biyu

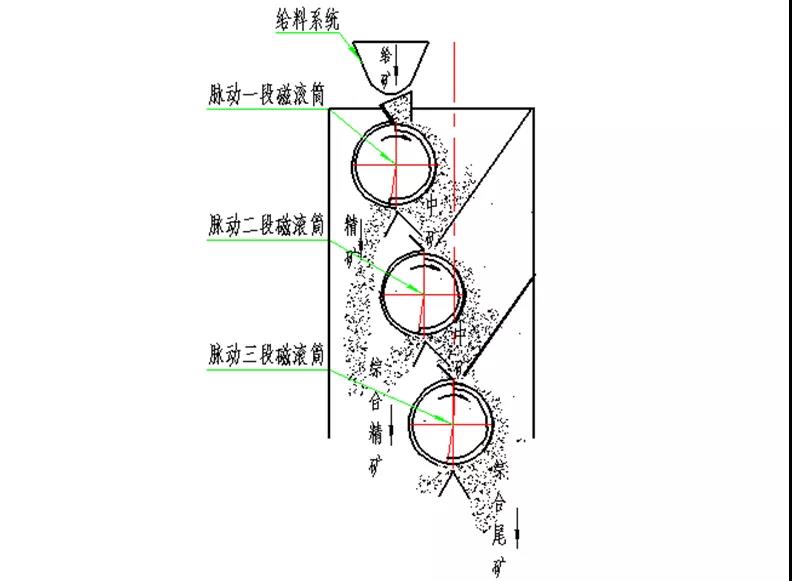

Kayan aiki suna shiga cikin ma'adinan ta na'urar ciyarwa, ana rarraba ma'adinan ta ganga na farko, kuma an fara fitar da wani ɓangare na abin da aka tattara. Wutsiyoyi na ganga na farko suna shiga cikin ganga na biyu suna share ganga na biyu, wutsiya na biyu kuma suna shiga na uku suna share ganga na uku, wutsiya ta uku kuma ta uku Don wutsiya ta ƙarshe, an haɗa manyan ganga na farko, na biyu, da na uku a cikin taro na ƙarshe. An nuna ƙa'idar aiki na ƙaƙƙarfan ƙaƙƙarfan da sharewa biyu a cikin hoto 9.

Hoto 9 Tsarin tsari na ƙa'idar aiki na ɗaya m da share biyu

Kayan aiki suna shiga ma'adinan ta na'urar ciyarwa. Bayan an jera tama da ganga na farko, mai da hankali ya shiga cikin ganga na biyu don ƙarin rabuwa, na biyun kuma ya shiga cikin rarrabuwar ganga na uku, na ukun kuma na uku shine na ƙarshe. An haɗa wutsiyoyi na ganguna na biyu da na uku a cikin wutsiya ta ƙarshe. An nuna ƙa'idar aiki na ƙaƙƙarfan ƙaƙƙarfan tara da tara biyu a cikin hoto 10.

Hoto 10 Tsarin tsari na ƙa'idar aiki na ɗaya m da lafiya biyu

Abubuwan fasaha na tsari

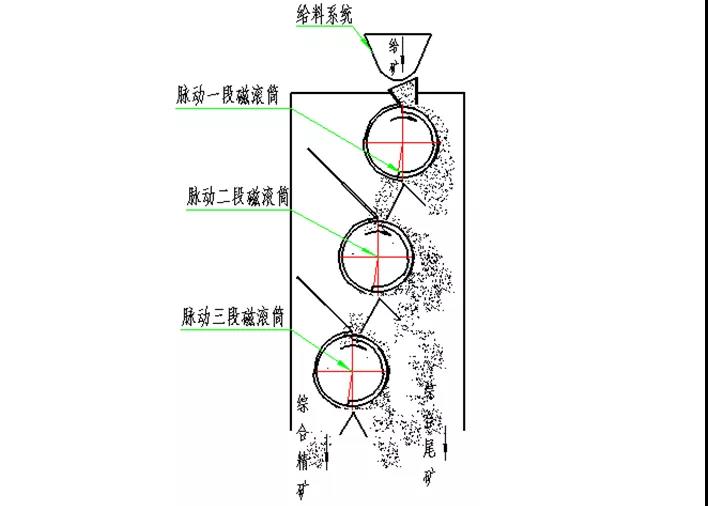

Technical maki na 3MCTF jerin uku-nadi pulsating busassun Magnetic SEPARATOR: ①Ainihin zane manufa iri daya ne da MCTF jerin pulsating bushe Magnetic SEPARATOR. ② Ƙarfin filin maganadisu na bututu na biyu da bututu na uku yana ƙaruwa a cikin tsari guda ɗaya da sharewa biyu; Ƙarfin filin maganadisu na bututu na biyu da bututu na uku yana raguwa a cikin tsari ɗaya mai ƙarfi da lafiya biyu. Ana nuna wurin aikace-aikacen na jerin 3MCTF mai busasshiyar ganga mai busasshiyar maganadisu a hoto na 11.

Hoto 11 Wurin aiki na 3MCTF mai busasshiyar ganga mai busasshiyar maganadisu

4. CTGY jerin m Magnetic juyawa Magnetic filin bushe Magnetic SEPARATOR

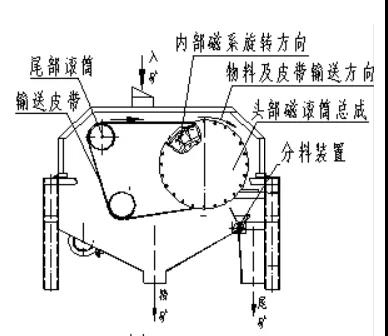

Ka'idar aiki na jerin CTGY magnet mai jujjuyawa mai jujjuyawar filin maganadisu busasshen maganadisu an nuna shi a hoto na 12.

Hoto 12 Ka'idar aiki na jerin CTGY na dindindin mai jujjuyawar maganadisu busasshen maganadisu.

CTGY jerin dindindin maganadisu mai jujjuyawa filin maganadisu pre-zaɓi [3] yana ɗaukar tsarin maganadisu mai haɗaɗɗiya, ta hanyar nau'ikan watsawa na inji guda biyu, ya gane jujjuyawar tsarin maganadisu da drum, yana haifar da saurin polarity canji, ta yadda magnetic abu zai iya zama. rabu cikin nisa mai nisa. Matsakaicin ya fi rabuwa gaba ɗaya daga kayan magnetic marasa ƙarfi da rauni.

Kayan yana faɗowa akan bel ɗin mai ɗaukar kaya ta hanyar tashar ciyarwa sama da na'urar ciyarwa, kuma bel ɗin yana motsawa ƙarƙashin aikin injin ɗin, kuma filin maganadisu yana jujjuya a gaban gaba a ƙarƙashin aikin motar (dangane da bel ɗin. .Bayan da kayan da aka kawo zuwa filin maganadisu ta hanyar bel na isarwa, kayan magnetic yana da ƙarfi sosai akan bel kuma an juyar da aikin motsa jiki mai ƙarfi, wanda ya haifar da juyawa da tsalle, da "matsi" abubuwan da ba na maganadisu ba zuwa ga Layer na sama na abu a ƙarƙashin aikin nauyi da ƙarfin centrifugal. , Da sauri shigar da akwatin mara maganadisu. Abun maganadisu yana adsorbed zuwa bel kuma yana ci gaba da gudana a ƙarƙashin drum. Lokacin da ya fita daga filin maganadisu, ya shiga akwatin maganadisu a ƙarƙashin aikin nauyi da ƙarfi na centrifugal don gane ingantaccen rabuwar abubuwan maganadisu da abubuwan da ba na maganadisu ba.

Abubuwan fasaha na tsari

Ainihin tsarin CTGY jerin m Magnetic juyi Magnetic filin bushe Magnetic SEPARATOR ya hada da firam, feed akwatin, drum, tailings akwatin, maida hankali akwatin, Magnetic watsa tsarin, drum watsa tsarin, da dai sauransu

Abubuwan fasaha na jerin CTGY na dindindin Magnetic juyawa Magnetic filin bushe Magnetic SEPARATOR: ① The Magnetic tsarin zane rungumi dabi'ar concentric juyi Magnetic tsarin, da Magnetic kunsa kwana ne 360 °, da kewaye shugabanci da aka alternately shirya bisa ga NSN polarity, da kuma musamman Magnetic taro fasahar ana amfani da shi. NdFeB wedge Magnetic block kungiyoyin ana kara tsakanin Magnetic kungiyoyin don yin drum Ƙarfin yana ƙaruwa da fiye da sau 1.5, kuma adadin igiyoyin maganadisu suna ninka sau biyu a lokaci guda, wanda ke ƙara yawan tumbling a lokacin aikin rarraba kayan. kuma iya yadda ya kamata jefa tafi da rauni Magnetic abubuwa da gauraye gangues a minerals.The high-yi, high-coercivity, high-zazzabi da high-zazzabi-resistant rare duniya neodymium baƙin ƙarfe boron da ake amfani da Magnetic Madogararsa, da Magnetic iyakacin duniya faranti ne. wanda aka yi da babban kayan aiki mai ƙarfi DT3 ƙarfe mai tsabta na lantarki, wanda ke haɓaka haɓakar haɓakawa sosai. Babban shaft ɗin yana rage girman asarar filin maganadisu, kuma ƙarfin filin maganadisu akan saman silinda magnetic yana inganta yadda ya kamata, wanda ke inganta ƙimar dawo da kayan ferromagnetic. Ana zaɓen injina guda biyu don sarrafa saurin ganga da jujjuyawar tsarin maganadisu bi da bi, kuma inverter guda biyu suna sarrafa na'urorin da aka haɗa da bi-biyu. Ana iya canza saurin motar ta hanyar daidaita mitar motar a lokacin da ake so, Ta hanyar canza saurin jujjuyawar ganga da saurin jujjuyawar tsarin maganadisu, ana sarrafa adadin ɓarnar ɓarna na ma'adinan ma'adinai. Ganga an yi ta da fiber gilashin ƙarfafa filastik da aka yi da resin epoxy, wanda ke guje wa dumama abin nadi kuma yana ƙara ƙarfin injin saboda tasirin eddy current.

5. CXFG Series Dakatar da Magnetic Separator

5.1 Babban tsari da ka'idar aiki

CXFG jerin dakatarwar maganadisu ya ƙunshi akwatin ciyarwa, na'urar rarraba abin nadi, babban bel mai ɗaukar bel, mai ɗaukar bel ɗin taimako, tsarin maganadisu, na'urar rarrabawa, na'urar tsayawa, akwatin tattarawa, akwatin wutsiya. , firam da watsa Tsarin tsarin.

Ka'idar rarrabuwar ka'idar CXFG jerin dakatarwar maganadisu ita ce yin amfani da injin abin nadi don ciyar da kayan daidai gwargwado zuwa saman bel ɗin isar da mai ɗaukar bel ɗin taimako. Tsarin maganadisu akan babban mai ɗaukar bel yana kan ɓangaren sama na kayan don raba ma'adinan maganadisu mai ƙarfi. Ana ɗauka a aika zuwa akwatin tattarawa. Lokacin da kayan maganadisu masu rauni suka wuce ta kan na'urar ɗaukar bel ɗin taimako, tsarin maganadisu a cikin ganga yana tsotse su a saman ganga kuma su fada cikin akwatin tattarawa bayan an raba su da filin maganadisu yayin da ganga ke juyawa. Ana jefa ma'adinan da ba na maganadisu ba a cikin akwatin wutsiya a ƙarƙashin aikin inertial ƙarfi na motsi da nauyi, don cimma manufar rarrabawa. An nuna ƙa'idar aiki na CXFG jerin dakatarwar mai raba maganadisu a cikin hoto 13.

Hoto 13 Ka'idar aiki na CXFG jerin dakatarwar maganadisu

Abubuwan fasaha na tsari

Technical maki na CXFG jerin dakatar Magnetic SEPARATOR: ①Amfani da counter-nadi irin zane ba zai iya kawai tabbatar da uniformity na aiki iya aiki da kuma abu Layer, amma kuma iya tsangwama da kuma taimaka murkushe manyan-hatsi tama. Akwai tazara tsakanin nau'i-nau'i biyu na rollers. Ana kora nau'ikan nau'ikan gear guda biyu don jujjuyawa tare da juyi ta hanyar rage mitoci akai-akai. Mai amfani zai iya daidaita saurin rollers guda biyu bisa ga fitarwa don daidaita adadin ma'adinai. Tsarin maganadisu na planar yana da yanki mai tsayi mai tsayi da tsayin lokaci na maganadisu, wanda ke haifar da ƙarin damar tallatawa ga ma'aunin maganadisu. Kuma saboda tsarin maganadisu yana kan ɓangaren sama na ma'adinan, ƙarfe na Magnetic A cikin yanki na rarrabawa, yana cikin yanayin da aka dakatar da sako-sako, ana tallata monomer, babu wani abin haɗawa, kuma ingancin inganta darajar shine. Fiye da na tsarin maganadisu mai lankwasa.Ma'adinan maganadisu suna tafiya tare da sandunan maganadisu kuma su wuce ta tsarin maganadisu na jirgin sama. Ana juya ma'adinan maganadisu ta atomatik sau da yawa. Yawan juyawa yana da girma kuma lokaci yana da tsawo, wanda ke da amfani don inganta darajar ma'adanai na Magnetic.A cikin tsarin magnetic planar, zane yana da bambanci mai mahimmanci da ma'ana mai mahimmanci, kuma ma'adanai suna ko da yaushe a ƙarƙashin aikin multi- Polar Magnetic Poles, wanda yadda ya kamata ya raba gangue da ma'adinan da ba na maganadisu ba, ta haka ne ke samun cikakkiyar farfadowa, inganta darajar mai da hankali da rage mai gudu Tail. ware kananan barbashi. Nadi yana ɗaukar tsarin tsagi don hana karkatar da bel.

A sama da aka ambata jerin kayayyakin samar da Shandong Huate Magnetoelectric Technology Co., Ltd. sun dace da rabuwa da ma'adanai na daban-daban barbashi masu girma dabam. Suna da nasu mai da hankali kan ƙirar ƙirar samfur don biyan buƙatun ma'auni daban-daban, kuma an yi amfani da su cikin nasara. A yawancin kamfanonin hakar ma'adinai, ya taka muhimmiyar rawa wajen ceton makamashi da rage yawan amfani da inganta inganci.

Kamfanonin hakar ma'adinai ya kamata su zaɓi kayan aikin magnetic rabuwa da suka dace da yanayin kasuwancin su gwargwadon yanayin ma'adinai da fasahar fasaha don haɓaka haɓakar samarwa.

Ya kamata masana'antun kayan aiki su ci gaba da haɓakawa da kammala aikin samfuransu bisa ga buƙatun samar da masana'antar hakar ma'adinai, magance wasu matsalolin da ake amfani da su a zahiri, samar da samfuran da suka fi dacewa da aikace-aikacen masana'antu, da haɓaka haɓaka fasahar haɓaka kayan aikin magnetic.

Lokacin aikawa: Maris 17-2021